ARTIFICAL LIFT

Advanced ESP lifting boosts field profitability

Using field-wide surveillance and production monitoring in real time, operators can optimize production and reduce Opex.

Valli Shanmugam, Aethon; Suhas Bodwadkar, Marc Pearcy and Jaime Gutierrez, Schlumberger

Real-time production monitoring and surveillance provide the tools to anticipate and prevent most pumping well-production problems, and to minimize those that cannot be prevented. In addition, advance warning of impending production problems allows operators to reduce costs by planning workovers before equipment fails. The ultimate goal is field-wide optimization, achieved by combining the operator’s reservoir knowledge with top-quality measurement technology and artificial lift capabilities. A production optimization simulator helps operators assess alternatives and evaluate proposals to determine their outcomes before making final decisions.

Aethon has been using Schlumberger advanced Electrical Submersible Pump (ESP) lifting technology to optimize 57 wells in four of its fields in Oklahoma and Texas. From a central production office, the company has implemented proactive ESP surveillance and monitoring to perform well diagnosis. In addition, scheduled “health checks” have revealed opportunities to improve pump performance and well productivity.

Initial results indicate that 20% of the company’s assets could be further improved, resulting in potential added value of $250,000 per month (based on $50/bbl market prices) from the combined effect of cost savings, reduced downtime and increased well productivity.

The system is not a cure-all. But it is an efficient, systematic and thorough way to evaluate production system performance, identify problems, postulate solutions and evaluate alternatives.

PROCESS

The advanced ESP lifting technology records and transmits real-time signals from a number of sensors embedded in key components of the ESP production system, using secure, two-way, Web-based communications. At the receiving hub, data is screened and validated, then routed to alarm and alert management systems and to the operator’s business process management system. The alarm system is programmed to send an alarm to field personnel if an undesirable condition is detected. This is designed to prevent catastrophic failures by giving personnel time to react to the problem. If it’s an emergency, field personnel can shut down the well immediately, using a coded command from a cell phone, Personal Digital Assistant (PDA) or laptop.

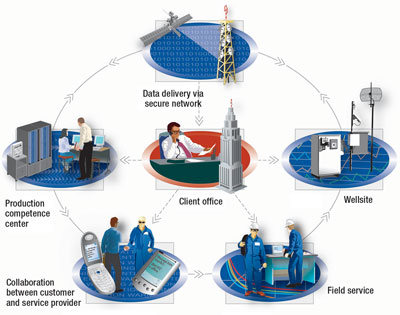

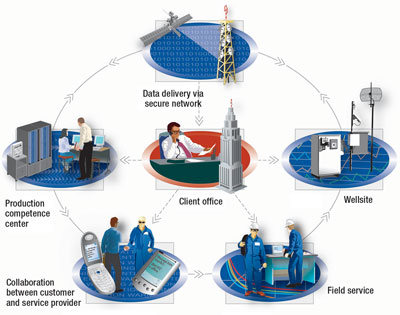

The alert system notifies the production monitoring team that a pre-set threshold for a parameter has been exceeded or a sub-optimal performance trend has been detected. When this occurs, team members can query the data server and recover historical data from the system for analysis. They can collaborate with experts both within the company or based at the service company, Fig. 1.

|

Fig. 1. The proprietary surveillance and control system offers remote data acquisition and control, timely alarms and dynamic storage of real-time updates. Historical data can be accessed for trend analysis and problem diagnosis by production experts who monitor the system.

|

|

The operator’s business process management system uses the data to measure production and production parameters and input them to a field management system whose goal is production optimization. Service company recommendations can be evaluated by calculating the net current value of incremental production improvements so it can be compared with the projected cost of producing the improvements. In addition, operating costs are quantified so economic analyses can be performed. With production metrics and operating costs, well and field lifting costs can be determined. Under-performing wells can be identified and diagnosed, and cost/value analyses can be employed to plan and prioritize remedial actions.

APPLICATION

Four examples illustrate the versatility of the system.

ECBSU field. In the East Criner Bromide Sand Unit (ECBSU) field in McClain County, Oklahoma, data from Schlumberger’s espWatcher monitoring system on the ECBSU 4-3 well triggered an alert. Pump vibrations were mounting, and intake pressure was on the rise. The well’s history was retrieved from the database and analyzed. A plot of intake pressure over time was prepared with vibration occurrence and amplitude superimposed. A preliminary report to the operator suggested possible pump deterioration, and a detailed analysis was performed. The current operating conditions were plotted against the actual pump-head-vs.-flowrate curve to check if the pump was functioning within its most efficient operating range. Comparisons of these parameters at 10 mo and 23 mo after pump installation told the story: In that time, the pump’s performance had degraded 30% due to wear, and this caused a 22% greater drain on electrical power, amounting to increased operating costs of $1,400/mo.

Aethon was able to maintain production by gradually increasing the speed of the pump over time, because the ESP was equipped with a variable-speed drive. But even so, it was clear that this was only a short-term solution. Analysis of the production system suggested that a new pump would boost production by 900 bbl/mo, or about $45,000. Considering the added production together with monthly electrical savings of $1,400, the new pump would quickly pay for itself. At press time, the pump was scheduled to be installed at the end of April 2007.

On another occasion, a sensor at the bottom of the ESP had picked up a pressure transient event after a well shut-in. Analysis indicated that the formation permeability was 28 mD and that there was no near-wellbore damage (skin of -3.1), leading the company to rule out formation treatment as a needless expense.

West Fitts field. At Oklahoma’s West Fitts field, in Pontotoc County, Fitts West 28-02 well’s annual physical found that the pump was operating within its recommended range, but that there was room for improvement. A short-term solution considered was to increase the frequency with a variable-speed drive and speed up the pump. Inflow performance analysis showed that this would boost production by about 360 bpd of total liquid (4 bopd), worth about $6,000/mo. But detailed analysis showed that the well was capable of much higher flowrate if a larger pump was installed. Accordingly, the long-term recommendation was to replace the ESP, raising production by 900 bpd of liquid (9 bopd), or $13,500/mo.

Further analysis of pressure transients in the Fitts West well revealed positive near-wellbore skin of 1.5, considerably higher than expected for a well in that field, Fig. 2. The inflow-outflow analysis showed that a formation stimulation treatment could reduce the skin effect, boosting the liquid rate by about 5,000 bpd (50 bopd). Factoring in the added pump capacity, production could be increased to 7,000 bpd of liquid (70 bopd). Together, improving inflow and boosting pump capacity could add $105,000/mo to the bottom line. Study is underway to determine the appropriate formation stimulation method for this well.

|

Fig. 2. Analysis of pressure transients at the Fitts West 28-02 well revealed a drop in the derivative behavior, indicating a constant pressure boundary, which was determined to be a result of a pressure drop due to water injection. Reservoir parameters like permeability, skin and distance to boundaries were then calculated from this analysis.

|

|

SWNLU field. A gassy oil well can pose major production headaches. At the Southwest Nina Lucia Unit (SWNLU) field in Coke County, Texas, 17 wells were under analysis. An alert on the SWNLU 45-3A well warned of erratic pump operation. Intake pressure showed a sharp rise followed by an immediate drop, indicating that something might be blocking the pump intake port. Before taking action on this alert, the team pulled records from other SWNLU wells and saw a disturbing pattern of erratic pump-offs. The pumps were automatically shutting down to avoid overheating damage. Automatic reset software would bring them back after a period only to have them shut down again. Calculating the cumulative effect of the shutdown periods, it was determined that the well was losing 18% of its uptime, or about 4.4 hours per day. At the production rate of 18 bopd, this represented lost production of 103 bbl/mo valued at $5,100.

Installing variable-speed drives could reduce shutdown time by 50�60%, but a better solution would be to try to find out the cause of the shutdowns. Reservoir analysis indicated that the wells were coning gas from the reservoir gas cap, and when gas broke through, the ESP sensor detected a rising motor temperature and shut the unit down on a pre-set temperature limit. As soon as the pumps shut down, the gas would recede, so when the pumps re-started they would pump liquid again for a while until the gas broke through again. Different wells were affected differently: Some experienced infrequent problems, but others were almost always shut down.

Several solutions mitigated the problem. By placing a gas shroud over the intake ports on four wells, the distance to the gas-oil contact inside the wellbore was increased. Several pumps were equipped with variable-speed drives so they could be “fine tuned” to pump at the maximum rate without coning gas. Seven wells were equipped with reverse-flow separators, and of these, two were equipped with advanced gas handlers. The operator also plans to use the workover opportunity to replace several degraded pumps where sub-optimal performance was indicated. The cumulative effect of these improvements was added profitability of $66,500/mo.

Dora Roberts field. By monitoring production parameters in a field using a system equipped with smart alarms, off-trends can be identified quickly. Such was the case in Dora Roberts field in Howard County, Texas. In January 2006, engineers monitoring the field got an alarm. Examination of the pump record for the Dora Roberts 38 producer showed a dramatic downward spike in intake pressure followed by an immediate increase in power load, Fig. 3. A check of the pump indicated that everything was working properly. Accordingly, it was concluded that a problem outside the well triggered the alarm.

|

Fig. 3. At Dora Roberts field, a real-time alarm warning of a sudden downward spike in a well’s intake pressure, followed by an increase in power load, triggered an analysis that revealed a more serious field problem.

|

|

Dora Roberts 38 production is supported by three offset injector wells. Two of them were injecting steadily; the third was not. The team analyzed the well’s injection profile and determined that as soon as it was shut in, the alarm went off in the producer because injection support was gone. Usually, identifying a conformance trend between field injectors and producers takes a long time, but with real-time data from the monitoring tool, the problem was detected immediately. A slight decline in oil production could be seen, but without the alarm it likely would have gone unnoticed for several months. By monitoring producing wells using the system, operators can quickly understand the effect of changes in the injection pattern.

CONCLUSIONS

Almost every oil company monitors well production, accumulating vast databases of well performance history. But often, time-impoverished operators have difficulty finding the personnel needed to process and analyze all the production data from numerous wells. More than 200 of Aethon’s wells are being monitored by the system. With systematic monitoring by production experts using efficient workflows and the latest equipment and software, together with two-way, Web-based communication and remote control, many problems can be eliminated before they occur, simply by recognizing the trends and sounding an alert. This frees the operator to address only those wells with serious problems requiring mitigation decisions. Even these decisions are facilitated by production system simulators and economic analysis software that help decision makers choose between alternatives and quantify the value of their choices.

|

THE AUTHORS

|

|

Valli Shanmugam is a petroleum engineer for Aethon I LP based in Dallas, a position he assumed in 2005. He oversees upstream operations with special emphasis on artificial lift and production optimization. Mr. Shanmugam previously worked for Schlumberger as a field engineer. He earned an MS degree in petroleum engineering at the University of Texas at Austin and a BS degree in chemical engineering at the University of Madras, India.

|

|

| |

Suhas Bodwadkar is production center manager for Schlumberger based in Oklahoma City. Dr. Suhas has 11 years’ experience in the industry. His core expertise is reservoir engineering, waterflood and field optimization. Dr. Suhas is the chairman of SPE’s Reservoir Geoscience Technical Interest Group. He earned a PhD degree from the University of Texas at Austin.

|

|

| |

Marc Pearcy is USLE north solutions manager for Schlumberger based in Oklahoma City, where he coordinates the activities of experts who support the company’s oilfield technology segments. He has over 26 years’ experience in the oil and gas industry. He has held many technical engineering positions throughout North America. His primary expertise is in reservoir and production engineering, with extensive experience in producing systems analysis. Mr. Pearcy has a BS degree from Texas A&M University.

|

|

| |

Jaime Gutierrez is production optimization business development manager for Schlumberger artificial lift, based in Rosharon, Texas. He has worked with Schlumberger since 1997 in positions including artificial lift operations manager for the Western US and Alaska and business development manager for the Western US. Mr. Gutierrez’s expertise includes mechanical engineering, application software and marketing. He is a member of SPE, ASME and SME. He has MS and BS degrees in mechanical engineering and an MBA degree from Texas A&M University.

|

|

|