Deepwater

Technology

Multiphase and wet gas metering provide a

low-capex solution

Combining virtual and physical meters provides wider control

of flowline networks for deepwater fields.

�ge Rasmussen, FMC Technologies, Kongsberg, Norway

The

benefits of metering the contribution from each well in a field may,

in general, be quantified by how efficiently the production system

is utilized at any point in time, and ultimately by the overall field

recovery factor. Recent studies by Statoil, Hydro and the Norwegian

Petroleum Directorate (NPD) show a 15% to 20% difference in recovery

factor from subsea to platform wells. 1, 2 Multiphase and wet gas metering

play an important role in closing this gap.

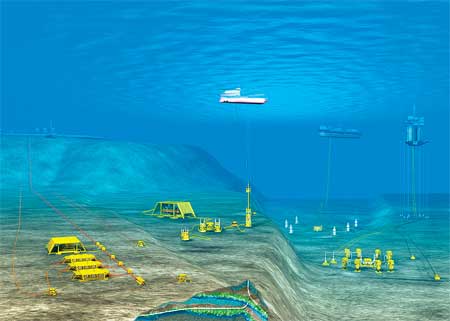

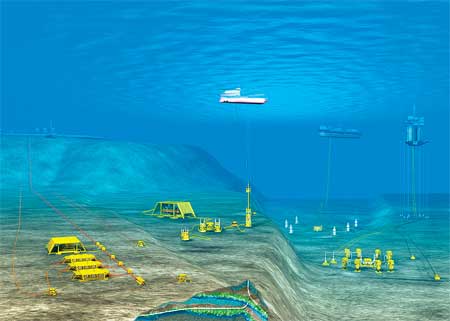

More and more offshore field developments, particularly in deep water,

are opting for a solution, where a large number of wells are tied back

to a limited number of flowlines, since this will provide the lowest

capex solution, Fig. 1. To add to the complexity, artificial lift may

be provided through a limited number of gas lift lines, or by a limited

number of booster or multiphase pumps. All these elements contribute

to increasing the number of variables to be optimized simultaneously,

which leads to an increase in the overall complexity of the production

optimizations. The basis for performing day-to-day production optimization

is having an accurate model of the full-flowing network, and accurate

measurements of current flowrates and flowing conditions at any point

in the flowing network. A combination of physical and virtual metering

may provide accurate metering and updated models, in addition to the

capability of performing short- and long-term optimization within the

same framework.

|

|

Fig. 1. Various subsea and platform-based field layouts. |

|

MOTIVATION

As developments move toward deeper water, the previously identified

issues become even more pronounced. Due to increasing cost and complexity

of operations with increasing depth, the potential benefit increases

proportionally, whereas the initial investment in an overall metering

and optimization system remains almost unchanged.

Enhanced potential through targeted

interventions. As stated above,

Statoil, Hydro and NPD have found an average difference in overall

recovery factor, between 15% and 20%, for a field completed with subsea

wells compared to a field with dry wellheads on a platform. 1, 2 For

deepwater developments, it is anticipated that the average recovery

factor will decrease as a function of water depth. 3 Obviously, the

main reason behind the decrease in recovery factor is the added cost

and complexity of performing interventions on subsea wells, factors

that are accentuated even further for deepwater developments. Improvements

in multiphase or wet gas measurement capabilities will not affect the

cost of subsea interventions. These improvements will, however, enable

the operator to target the correct wells. Increasing the amount of

information available from each well will enable the operators to target

the correct wells, and to ensure that the correct intervention type

is performed. Together with developing technologies such as light well

interventions, quality flowrate measurements may contribute to increasing

the recovery factor from subsea and deepwater production systems.

Enhanced potential through production

optimization. To add production

capacity to existing facilities, or to develop fields at a minimum

investment, we are seeing a trend toward more complex field layouts,

Fig. 2. A typical manifold layout for a subsea development may be seen

as a 4-or-6-slot manifold tied back to the production facility through

one or two flowlines. To expand this layout at a minimal cost, it is

much cheaper to daisy chain a second manifold on the back of an existing

one, than to include a second stand-alone manifold with separate flowlines.

For a new field, a two-manifold daisy chain configuration reduces the

necessary number of flowlines and risers.

|

|

Fig. 2. Increasingly complex subsea layouts are required by fiscal realities. |

|

Obviously, the flowline and riser sizes will increase, but the flexibility

of such a configuration will only be moderately reduced compared to

the two-manifold/four-riser option. This solution's drawback is the

added complexity of producing through the networks. Taking into consideration

the need for artificial lift, either as gas lift or through boosting

or multiphase pumping, the complexity of optimizing production increases

significantly. The potential benefit from accurate measurements of

production from each well increases significantly with the geometry's

complexity.

Figure 3 shows an illustration based on production profiles from the

Troll B field. The figure shows the difference between best-case flexible

routing (blue line), and fixed-well routing (magenta line) over life

of field for a four-well manifold tied back to the platform through

two flowlines. The curves show a comparison between a fixed routing,

and an optimized flexible well-to-line routing. To be able to realize

the potential that lies within optimizing field production, it is essential

to have accurate knowledge of produced flowrates from each well at

all times. Any optimization tool is dependent on an accurate model

of the production system. The quality of flow optimizations is linked

to the quality of the model, which in turn is dependent on the accuracy

of the measured flowrates.

|

|

Fig. 3. Optimized vs. fixed routing production. |

|

Enhanced reservoir modelling potential. Values from Statoil on Gullfaks

field show an increase in expected ultimate recovery factor from 46%

in 1996 to 61% in 2004. 4 The increase is attributed to several factors,

including advances in reservoir modeling. The reservoir models are

based on a variety of data from 4D seismic to production logging. However,

accurate drainage and injection distribution measurements are a necessary

building block to provide accurate reservoir models.

CURRENT ALTERNATIVES

Operators contemplating subsea developments must make a choice between

specifying just physical meters or going with a virtual metering option.

The advantages and disadvantages of these options are described in

the following passages.

Physical meters. All subsea multiphase or wet gas flow meters (MPFM

or WGM) face the common challenge, that the property they seek to measure,

the volumetric or mass flow of each of the flowing phases, does not

lend itself to direct measurement by currently available technology.

To measure the volumetric or mass flow directly, the fluids must first

be separated, and then measured. As this is not a practical subsea

solution, or even practical for most topsides applications, the meters

are restricted to measuring primary variables, and companies resort

to calculation software to calculate flowrates based on the primary

measurements. This requires a model description of the fluid flow,

and an algorithm to calculate flowrates based on primary measurements.

Figure 4 shows a typical logic diagram for a WGM/MPFM. 5

|

|

Fig. 4. WGM/MPFM logic diagram.5 |

|

The primary sensing elements used range from direct measurements,

such as pressure and temperature, to more advanced sensing elements

that require calculation and interpretation, such as velocity cross-correlations

and Gamma densitometers. Different vendors use different combinations

of primary sensing elements that give strengths and weaknesses for

different combinations of the three flowing phases. A meter designed

to calculate three flowing phases is, as a matter of principle, dependent

on a minimum of three primary sensing elements to achieve a mathematically

defined problem.

Each primary sensing element is subject

to an inherent error or inaccuracy. The total error of the multiphase

or wet gas calculations will reflect the sum of the errors of the

individual sensing elements, and the error of the applied flow model.

A differential pressure measurement across a reduction in flowing

area is, together with pressure and temperature sensors, probably

the most widely employed primary measurement in WGM and MPFM technology.

To give an accurate reading of the overall mass flow from a venturi

meter, the flow calculations algorithm must have an accurate description

of the density of the each of the flowing phases. If the PVT model

used in the flow calculations does not accurately depict the actual

flowing properties, the results will contain certain errors. This

reflects the greatest challenge to multiphase metering today�the

effect of changing fluid properties, and the inability to detect

these changes.

To be able to meet their specified accuracy, many meter vendors require

special circumstances, such as in-line calibration, or a requirement

of only saturated water production at start-up (no free water production).

Due to the complexity of many of today's production systems, it may

not be possible to achieve reference measurements for meter calibration.

In addition, most of the primary sensing elements detect a variable

that is dependent on flowing fluids' PVT properties. The calculation

software must reflect the correct PVT properties to yield a correct

flow split. For most reservoirs, the fluid composition will vary over

time. This, in turn, will result in decreased accuracy. Some meters

have facilities for providing fluid samples to rectify this problem.

This leaves the operator with the challenge of collecting and analyzing

samples at a regular interval.

Virtual metering. The term, virtual metering,

may be described as the concept of calculating flowrates, based on

all available sensory information distributed throughout the production

network. Virtual metering may be performed online or offline�the

only prerequisite is that all sensory information is gathered within

the same timeframe, to facilitate the computational models used.

The basic idea is to combine the sensory input with the numerical

flow models.

The virtual meter calculates a flow field through the entire production

system. The flow field will inherently contain the calculated sensor

responses at all sensor locations. The discrepancies between measured

and calculated properties are quantified within an object function,

and the object function is minimized through an iterative search. The

procedure is described in its simplest form in Fig. 5. 6 It shows how

the analytically solvable problem of single-phase flow through a venturi

can be solved iteratively by imposing an object function.

|

|

Fig. 5. The concept of the object function. |

|

The one-dimensional problem lends itself

more easily to illustration than the three-dimensional problem consisting

of three flowrates�oil,

gas and water�flowing through a production well with multiple sensors.

The principle, however, is the same.

Figure 6 shows the operating principles of a virtual meter. All required

information is fed into the model, either on an on- or offline basis.

The model makes an initial guess of the rates and calculates the equivalent

sensor responses. The discrepancy between the measured and calculated

system responses is quantified through the object function and evaluated.

The procedure is repeated iteratively, until the value of the object

function reaches one of a set of cut-off criteria.

|

|

Fig. 6. Oil well with standard instrumentation.6 |

|

To obtain a well-posed mathematical problem, there must be at least

one measurement per unknown, the unknowns being the three flowrates.

The previous figures demonstrate the procedure with one and three unknowns.

The system can be expanded to a full converging network of wells and

lines. Recent software implementations have included the production

separator measurements and/or the fiscal export measurements. By increasing

the number of available measurements, the calculations will become

over-determined, and the virtual meter will become increasingly redundant

toward errors and failures in individual sensors.

One of virtual metering's major benefits is the accessibility of data

and calculations. Where most physical meters provide the results directly,

the virtual meter allows for a higher degree of interpretation and

user interaction. Not only the flowrates are reported for each time

step, but reporting and trending of the error function also give an

indication of the calculations' quality. A typical scenario for a virtual

meter is loss or error in one or several sensors. If the remaining

number of sensors no longer provides adequate information to obtain

a unique solution, the software allows for a reduction of the number

of unknowns to obtain a mathematically defined problem. Typically,

this may be done by introducing restrictions to the water-to-liquid

or gas-to-oil ratios. The restrictions or limitations may be imposed

as a function of any variable available to the calculations. The obvious

example would be to introduce a fixed, time- or rate-dependent correlation

to describe the changes in ratios. A different alternative is to use

the knowledge obtained through reservoir simulations to describe the

ratios as a function of bottomhole pressure and/or temperature.

A prerequisite to apply restrictions in the ratios is that the software-based

solution has the ability to include sporadic or non-continuous measurements

as part of the analysis. As opposed to a physical meter, the model

used in the virtual meter will continuously be updated toward all available

measurements, including sporadic non-continuous information, such as

direct well tests or deduction tests. A trend in any production characteristic

seen from one well test to the next may be extrapolated into the future

to aid the calculations. In the same way that trends and developments

may be utilized for predictions, the virtual meter also has the ability

to revisit previously calculated time periods. Contrary to a physical

WGM or MPFM, the virtual meter contains storage facilities to recalculate

all data. Should calculated flowrates be based on a perceived trend

or a sensor response that at a later stage is proven erroneous, all

results may be recalculated, based on the updated data. As stated in

the motivation section above, the primary benefit of accurate metering

on a day-to-day basis is the input provided to perform short-term optimization.

The long-term benefit of providing accurate information to the reservoir

models will be ensured, even if rate calculations are redone at a later

stage.

As described for the physical meters, virtual meters are also dependent

on an accurate description of fluid properties. Should the actual flowing

fluid differ significantly from the compositional description used

in the software, this will result in a reduction in the quality of

calculations. There is no technology available that can provide continuous

or intermittent sampling of fluid properties or composition, subsea.

To get an accurate composition, a laboratory test is the only quality

solution. The quality of results will also depend on the quality of

the analyzed sample. Sampling and analysis of fluid composition and

properties form a whole separate field, but a field that has great

bearing on the quality of the results obtained from a virtual or physical

meter. Due to the virtual meter's ability to continuously report an

error function, it will give an indication of the quality of calculations.

This may, in turn, be interpreted as an indication of the need for

updated fluid characteristics.

Data validation. FMC's virtual meter, FlowManager, uses a number of

data validation operations prior to utilizing any data for flow calculations.

All imported data are evaluated statistically to ensure that the values

are probable. The statistical evaluation employs simple principles,

such as maximum and minimum deviation, and rate of change to verify

sensor quality. The software also contains features for recognizing

certain scenarios, where multiple sensors should detect the same quantity.

As an example, a WGM is typically mounted upstream of the production

choke. The conditions at this position are essential for production

control and optimization, so a typical field will have stand-alone

pressure and temperature sensors at about the same location. Continuously

comparing the sensor values, and comparing these values to the model

responses, gives an indication of both error and a trend in error development

(drift) for each of the sensors.

A different example is sensors that only sporadically should show

the same value. For the typical FMC subsea tree, the upstream choke

sensors are mounted between the master and wing valves. Intermittently,

the wing valve will be closed, while the master and choke valves are

open. For this scenario, the upstream and downstream choke pressures

should be nearly identical. If they are not, this will indicate an

error in one or both sensors.

By analyzing the production system, it is probable that a large percentage

of sensors may be subject to intermittent verification. By using this

information actively, the quality of reported flowrates will increase

significantly.

COMBINED SOLUTIONS

The main challenges for both physical and virtual wet gas and multiphase

meters are the quality of individual sensing elements, and the fluid

properties that calculations are based on. By combining WGM or MPFM

technology with a virtual meter, the system may become over-determined,

and to a certain degree redundant toward errors in individual sensors.

To calculate flowrates at any point in the production system, a virtual

meter depends on having at least three measurements to find a unique

solution. The same applies to a physical meter that depends on a minimum

of three measurements to calculate three flowing phases. By importing

data from the primary sensing elements of the physical meter into the

framework of a virtual meter, the number of available measurements

will increase.

Any fluid or flowing property that can be both measured and modeled

is available to be included in a virtual meter. In this sense, a virtual

meter can be used as an addition to, and a substitute for, traditional

multiphase meters, if adequate measurements are available. The virtual

meter can incorporate individual sensor readings that a multiphase

flowmeter consists of, or it may use the calculated rates directly.

Readings from the multiphase meters are incorporated with all other

measurements within the production system, to give a best fit solution

for the entire package. In many fields where multiphase meters are

employed, lack of reliability caused by discrepancies between the sum

of all meters and the fiscal measurements causes uncertainty in all

measurements. The virtual meter is not limited to giving a spot reading

at the sampling position. Thus, it may be used as a supervision tool

to establish the most likely source of error.

To enable the software to use separator measurements, or the results

from a multiphase meter, it is necessary to have a solution that allows

for a controlled difference between the measured and calculated quantity.

The software contains a weighted object function. Assigning different

weights to the different measurements allows the user to accentuate

or discard certain measurements. In an over-determined system, this

feature gives an operator the possibility to use the system for sensory

evaluation.

Additional benefits. Measuring the flowing

phases does not in itself provide added value�the value comes from

how this information is used in production planning, production optimization

and in reservoir modeling. Traditionally, operators have used data

from well tests to calibrate models of wells and pipelines for production

planning and optimization. Employing a combined solution will give

a continuous verification of well model quality, as the sum of all

production is verified continuously toward topsides separator measurements.

It will also employ all available information to provide, as accurately

as possible, a prediction of the flowing phase rates at any point

in the production system. Both production planning and optimization

will improve, due to the improved accuracy of the employed models.

By employing such a tool, the added benefit of having a full mathematical

description of the flowing network may be used to perform a variety

of tasks. Online production optimization may be performed on a regular

basis by production engineers, or it may be performed as a fully automated,

set interval optimization that provides the best possible choke settings

for production and gas lift chokes, and routing recommendations. The

optimization run by the software is designed around enforcing various

system constraints and optimizing toward these constraints. The software

also contains facilities for closed-loop choke control. This means

that a field may be run in fully automated mode, where choke positions

are taken directly from the optimization recommendations.

Employing the complete system may not only improve the field's overall

efficiency and recovery factor, it may also limit the manpower needed

to run the field, and enable more personnel to work remotely.

CONCLUSIONS

Virtual and physical metering are rapidly developing technologies

facing many of the same challenges. The main challenge for multiphase

flow metering at the current state of technology is the inability to

directly detect changes in the compositions of the produced fluids.

However, by incorporating the two metering principles in a common framework,

the number of available measurements may be sufficient to detect changes

in fluid properties, if not to detect changes in the composition directly.

The two technologies also face common challenges related to sensor

quality. At the very least, this issue should be dealt with by using

continuous statistical surveillance of all sensors' reported values.

By evaluating trends over time, and taking advantage of distinct situations

where multiple sensors are exposed to similar or identical conditions,

the data quality, and subsequently the value of each sensor, will increase

significantly.

Incorporating all available data from the production system, including

the WGMs/MPFMs, in the framework of a virtual meter paves the way for

closing the gap between obtaining relevant data, and turning the information

into increased revenue.

LITERATURE

CITED

1

Karstad, P. I., “Subsea

IOR challenge and technology solutions,” Statoil presentation

at SPE, April 2004.

2 http://www.npd.no/English/Aktuelt/havbunn_utv_grad.htm

3 Laherrère, J. H., “Future sources of crude

oil supply and quality considerations,”

DRI/McGraw-Hill/French Petroleum Institute conference,

June 1997.

4 Hesjedal, A., ”Increased oil recovery on Tampen,” Statoil

presentation

to Morgan Stanley, North Sea Conference, May 2005.

5 Cunningham, C., E. Fjøsna and K. Berg, “Combined physical

and virtual multiphase metering for redundancy and synergies,” Deep

Offshore Technology Conference, November 2004.

6 Rasmussen, Åge, “Field applications of model-based

multiphase flow computing,” North Sea Flow Measurement Workshop,

October 2004.

|

THE

AUTHOR |

|

Åge

Rasmussen is a specialist engineer in Flow Management for FMC

Technologies. He holds an M.Sc. degree in Fluid Mechanics from

the Norwegian University of Science and Technology (NTNU). Mr.

Rasmussen joined FMC's FlowManager department in 2000, and has

since been involved with all aspects of the software, from model

calibration to software development. He currently works out of

FMC's Australia office in Perth, providing flow assurance and

field development support for FMC's customers in the Asia Pacific

region. |

|

| |

|