DRILLING AND WELL COMPLETION

Solving centralizer damage in ER horizontal multilaterals

Damage sustained after exiting casing windows at Alaska’s West Sak field development prompted modeling and yard tests to solve the problem.

Erick M. Peterson, Eric R. Davis and Mike R. Greener, ConocoPhillips; Daniel T. Craig, Baker Oil Tools

Several recent failures of centralizers run through casing exits have resulted in significant lost time associated with fishing and milling lost pieces of centralizers, to place the wells into proper service. After three such failures, the requirement to study the passage of a centralized liner through a casing exit became essential. Torque and drag modeling provided the down and side force estimates exerted on the liner and centralizer as they passed through a casing exit. A test fixture was utilized to simulate liners being run through a casing exit. Several potential centralizer candidates were tested, using the loads estimated from modeling.

This article discusses the problems noted in the installation prior to testing, details the modeling used to determine loads being exerted on the centralizer at the window, shows results of the yard tests conducted on several commonly utilized industry centralizers, and makes recommendations.

BACKGROUND

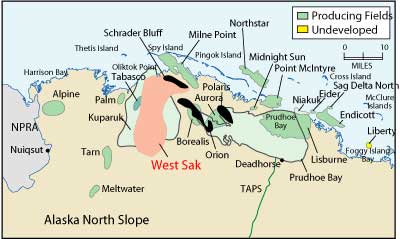

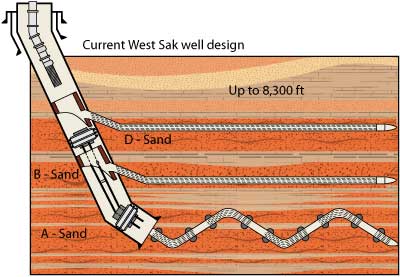

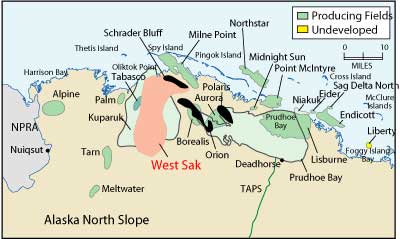

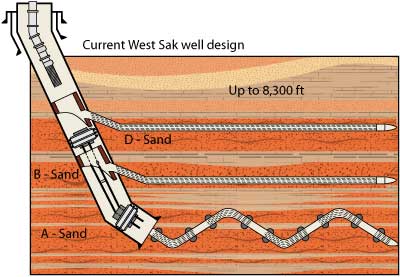

The West Sak oil reservoir is part of a large viscous oil resource overlying Kuparuk River field on Alaska’s North Slope, Fig. 1. Since the development of the North Slope, numerous pilot projects have attempted to economically produce the viscous West Sak oil. However, none of these projects has resulted in commercial development of the resource until recently.2,3 Advances in drilling, and a detailed study into sand management, have led to an economically viable project utilizing extended reach, slotted liners in dual and tri-lateral wells.1 The typical West Sak tri-lateral producer is shown in Fig. 2.

|

Fig. 1. Alaska North Slope location indicator.1

|

|

|

Fig. 2. Current West Sak field development well design.1

|

|

TYPICAL WELL CONSTRUCTION

The typical West Sak tri-lateral well is constructed by running the intermediate casing string through the entire West Sak formation, which is composed of multiple, distinct sand zones. Each lateral drilled from the mainbore will target a specific sand reservoir, typically the West Sak A, B and D. The lowermost horizontal lateral is drilled out through the intermediate casing shoe, and the slotted liner is run with a conventional hydraulic set liner hanger and liner top packer. A whipstock is then utilized to mill a casing exit in the intermediate casing, in the middle sand.

The intermediate casing inclination is typically between 75° and 80° across West Sak, and the casing exit is usually milled within 15° of the casing’s high side. The middle horizontal lateral is drilled, followed by retrieval of the whipstock. The milled casing exit typically has sharp edges. With the whipstock removed from the wellbore, the liner must pass through the sharp casing exit. For the slotted liner to run through the casing exit on the casing’s high side, a bent joint is run on the liner bottom. With the slotted liner run out the casing exit and into the lateral, the liner is installed in the casing exit with a HOOK Hanger.4 On the following trip, a Lateral Entry Module (LEM) is installed through the hanger to provide future thru-tubing lateral access. The process is repeated for the upper lateral..

|

|

|

|

This article was adapted from a professional society paper for which World Oil was granted the right to print one time only. Therefore, to review the article, you should refer to the actual World Oil magazine in which it originally appeared.

|

|

|

|

|

|

|