New products

New product and service offerings from company press releases.

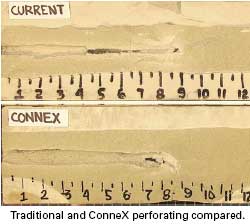

Self-cleaning jet perforation technology

GEODynamics Inc., Shell International E&P and QinetiQ plc have announced a new technology called ConneX Perforating. Shaped-charge perforating has been commonly employed since the early 1950s. This new technology employs an explosive cavity effect coupled with a metal liner to maximize penetration. Once the main explosive is detonated, the liner collapses to form a high-velocity jet of fluidized metal particles that are propelled outward. Perforation is achieved from impact of the initial portion of the jet traveling at about 30,000 ft/sec. An undesirable side effect of perforating is damage to the formation caused by the impact pressure, which propels steel, cement, rock and wellbore fluids into the surrounding formation. It also damages rock, pulverizing formation grains and leaving loose debris in the newly created tunnels, limiting well productivity and injectivity. With ConneX perforating technology, upon detonation, a secondary reaction is created within the perforation tunnel. The reaction is formed by use of new liner technology, incorporating a carefully controlled combination of bimetallic liner material that is pressed under very specific conditions. A strongly exothermic intermetallic reaction between liner components is induced by the shock upon detonation. This secondary event occurs within the perforation tunnel in microseconds after it is formed, and effectively “cleans” the perforation tunnel of debris and removes crushed material from the tunnel wall, leaving a near-ideal and optimized flow path. The perforating charge is compatible with existing gun technology and traditional perforating procedures.

Automatic hacksaw feed clamp system

A portable pipe clamp system with automatic feed is available from CS Unitec for use with the company’s portable pneumatic hacksaw. The system readily attaches to the hacksaw and pipe, and operates off of the same 90-psi air supply as the saw. The self-feeding device allows automatic cutting of pipe up to 30-in. diameter. The 1.5-hp Pneumatic Hacksaw has a stroke of 2 3/8 in., makes up to 350 strokes per minute, and will cut 4-in. to 30-in.-dia. pipe in one pass. It can make 90°cuts when attached to the pipe clamp, and the combined system weighs just 43 lb. High-speed saw blades are available up to 37 in. long. Special molybdenum alloy blades are available for stainless steel and super alloy pipe.

High-speed rotary pump Viking Pump has released a new high-speed rotary transport pump, the RTP20. Offering configuration flexibility and ease of maintenance, the RTP20 (1.0 liter/rev) is built with all the features of the larger RTP30 (1.28 liter/rev) design. The tri-lobe design, customizable per customer specifications, is compact and lightweight and features removable feet and multiple mountings for easy vertical or horizontal adaptation. The RTP20 series is also available with ACME threaded or tri-clamp ports, as well as many other port connection types. The pump efficiently fills rotor voids, allowing for faster and quieter operation on viscous liquids. With a longer sealing land at rotor tips, it provides enhanced efficiency when working with lower viscosity products. The RTP20 offers a capacity to 264 gpm, pressure to 145 psi, viscosity to 250,000 ssu, and operating temperatures to 230°F. .

Well modeling software WellFlo 4.0 well engineering software application from Weatherford International Ltd has been completely redesigned to function more intuitively, provide more powerful features, closely match constructed well models to reality, and present a richer GUI, allowing users to do more with the models and data. The software works with naturally flowing well applications, gas and condensate wells, pipeline and surface equipment. It provides modeling, design and analysis for electric submersible pumps and gas lift, inflow and outflow performance modeling and other applications. It was specifically designed to aid petroleum engineers with five basic well completion and production engineering functions: configuration, tuning, analysis, design and output.

Safety harnesses

Bacou-Dalloz has introduced the new Miller Derrick/Oil Rig harnesses and accessories. Featuring the innovative Miller Revolution harness technology, the specially designed derrick/oil rig harnesses offer greater mobility with PivotLink rotary connection. The modular attachment design also provides connection points for a complete line of tool belts and accessories for easy snap-on/off flexibility. Specially designed harness suspension loops provide greater mobility when climbing the rig, the D-ring positioned on the back of the belt maintains positioning on the tube board, while the D-ring extension on the back allows freedom of movement when connected to the block at the top of the rig. The harnesses are available in two webbing options: DualTech webbing--two-sided, contrasting color and textures engineered with shape-retention memory for comfortable fit; and Non-Stretch webbing, which is strong and durable. All Miller fall protection products meet applicable OSHA, ANSI and CSA requirements.

Petroleum emulsion breaker Planet Resource Recovery, Inc. has introduced PetroLuxus 500, a new aqueous emulsion-breaking product for the oil & gas sector. The product is available for a wide range of hydrocarbon emulsion-breaking applications throughout the full crude oil stream, from drilling and operations, to refining and storage. When introduced into an emulsion, it disperses rapidly while eliminating the interfacial surface tension between oil and other materials such as water, metals, dirt, sediments and other contaminants. The product works rapidly, usually within several hours, to effect separation of hydrocarbon emulsion components, resulting in a stratification of materials by specific gravity, providing an efficient method for the remediation and recovery of the components. It is non-hazardous, non-flammable and biodegradable.

Flare ignition system John Zink Co. introduced its WindPROOF InstaFire, a flare ignition system with a rapid response capability and three levels of detection and relighting redundancies for uninterrupted performance. WindPROOF technology is capable of operating in extreme weather conditions. The InstaFire system is stable in high winds, consumes as little as 45 scf/h of natural gas, and exceeds API Standard 537 recommendations.

Quartz electronic memory gauge

The PPS28-200C Quartz Memory Gauges from Pioneer Petrotech Services Inc. are developed for critical well testing in hostile well conditions. With metal-to-metal and elastomer seals and Inconel housings, these gauges are designed to gather high-quality data in extreme downhole conditions. To increase reliability, the electronics are in a replaceable cartridge that can be easily changed by personnel without any electronics background. The gauges also use simple software, PPS SmartView, making them easier to run by personnel with limited computer experience. Applications include pressure build-up, drillstem tests, production tests, post stimulation evaluation, interference tests and frac monitoring. Pressure range is up to 25,000 psi, with an accuracy of ±0.02% (full scale). Temperature rating is to 392°F.

Fluid dynamics software

Flomerics Group plc will provide its Engineering Fluid Dynamics (EFD) simulation software to universities and colleges around the world for teaching and research. Unlike traditional computational fluid dynamics (CFD) simulation software, EFD operates inside the mechanical CAD tools that engineers are familiar with, without any transfer of data. This allows users to skip the most time-consuming aspects of CFD software-the need to learn a new interface. Also. there is no CAD export, and meshing is fully automated. The EFD product family provides full-featured general-purpose fluid flow and heat transfer analysis software combining all simulation steps, starting with reading CAD data, model definition, mesh generation, solving, post-processing, through the generation of presentations, all within a single software environment. The software can simulate a wide range of engineering tasks, from creeping non-Newtonian flows to supersonic gas flows with high Mach numbers. Instrumentation tube fittings Parker Instrumentation’s Phastite is a new design of tube connectors that can deliver cost savings to builders of industrial equipment involving fluids. Assembled by a simple push-fit operation, the connectors provide permanent connections for fluid systems operating from thin- to heavy-wall, instrumentation-grade tubing. Phastite employs a compression assembly principle using a novel form of toothed profile, which makes the seal. Connectors are supplied as one-piece components. To make a joint, the tube is inserted, and then the collar is pushed along the connector body until it reaches a dead stop. The operation takes seconds and is performed by a handheld hydraulic tool. Inside the connector is a sealing system, based on a collar, which slides along a tapered body, in the process compressing a number of circular profiles into the tubing. At the end is a vertical face, which provides “dead stop” confirmation of correct assembly. The connectors includes straight union, union elbow, T and union cross shapes in sizes from 1/4 to 1/2 in. or 6-12 mm. |

|||||||||||||||||||