New products

New product and service offerings from company press releases.

Boost pipeline flow efficiency  Lowering the viscosity of crude by heating or introducing high-molecular-weight polymers into the pipeline stream can increase throughput by reducing friction, so it is critical that pipeline operators continuously monitor viscosity and temperature of flowing products. The BiODE acoustic wave viscometer is an on-line instrument, no bigger than a matchbox, that can be incorporated into the pipeline to feed continuous viscosity and temperature measurements to monitoring and security systems. These sensors provide an operating shear rate several orders of magnitude higher than fluid-flow characteristics – unaffected by static, laminar and turbulent flow – to accurately measure viscosity from 0 to 10,000 cP. The sensor consists of a proprietary quartz crystal chip in a hermetically sealed abrasion-resistant package. As the acoustic wave penetrates fluid hydrodynamically coupled to the surface of the sensor, viscosity is calculated by measuring power loss. Since the sensor contains no moving parts, it does not require calibration. With a WEB interface for real-time viscosity view through an intranet and USB, the new sensor can be easily integrated with existing instrumentation and control systems.

Activate chemical cutting tool AnTech Ltd has introduced a new Chemical Cutter Firing Head. It is designed to activate a chemical cutting tool without electrical cable. The chemical cutter requires a pin to strike an explosive charge with just the right amount of energy to ignite it. The firing head achieves this hydraulically by building up a precise amount of differential pressure behind the firing pin. With a 13/16-in. diameter, the firing head is designed for running on small-diameter tubing or 1-in. coiled tubing when cutting deviated or horizontal wells. Larger diameters are also available. The firing head features an integral ball release and fishing neck, so that if the cutting string becomes stuck, a ball can be dropped and a controlled release can be carried out immediately. In addition, the firing head features dual non-return valves so it does not need to be fitted with a separate valve sub, keeping its overall length to a minimum.

Mathematical modeling SGI Star-P parallel mathematical modeling software, combined with SGI Altix servers, allows the solving of complex algorithms and mathematical models in MATLAB or other Very High Level Language environments. It accelerates time-to-solution up to 30-fold. This solution transparently links desktop MATLAB environments with Altix compute capabilities, seamlessly blending the interactive desktop tools with high-performance computing. The software platform gives desktop users access to hundreds of gigabytes of memory and tens to hundreds of CPUs, greatly increasing the compute power of interactive tools for handling larger data sets and more complex algorithms. Industry-standard Linux operating systems are fully supported.

Bits for rotary steerable applications  Halliburton Security DBS Drill Bits is offering a new brochure on its HyperSteer and FullDrift drillbits for all rotary steerable applications. This new family of drillbits is designed for both push-the-bit and point-the-bit drilling systems. Each rotary steerable bit is custom-designed to optimize directional control, vibration and borehole quality. They are based on the company’s FM3000 fixed-cutter technology platform, with Z3 cutters. The full-color brochure features a dynamic gatefold with illustrations of key aspects of bit optimization and software design tools.

Auto-shutoff hose assembly A unique hose assembly protects personnel by automatically shutting off flow in both directions the instant a hose failure takes place. The Smart-Hose Safety System from Smart-Hose Technologies connects a coated cable within the hose bore to the valve plungers, wedges or flappers at hose end points. Acting as a compression spring, this cable will hold valves open when conditions are normal. The instant thrust is eliminated due to coupling ejection, hose stretching or hose separation, both valves seat themselves, stopping all flow in either direction. Smart-Hose Technologies has received US Department of Transportation exemption for railcar unloading, tank car loading and the requirement of a passive device for the loading and unloading of compressed gas cargo tankers.

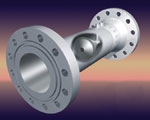

Compact flow meter  McCrometer’s V-Cone Flow Meter has been certified for oil and gas service by Petroleum Development Oman. The flow meter requires virtually no recalibration or maintenance over a long life, accurately measures disturbed flow and doesn’t require the upstream and downstream pipe runs of other flow meters. Designed for measurement of liquid, steam or gas, and suited for tough applications, the flow meter supports a wide range of applications. The V-Cone’s highly compact, no-moving-parts design keeps operating costs down for applications such as oil and natural gas production, raw material refining and petrochemical production. The meter relies on an advanced differential pressure flow sensor designed with built-in flow conditioning to achieve an accuracy of +0.5%, with a repeatability of +0.1%. It operates over a flow range of 10:1, and comes in line sizes from 0.5 – 120 in. With its ability to self-condition flow, the V-Cone Flow Meter eliminates the need for up/ downstream straight pipe runs required by other DP technologies, such as orifice plates and venturi tubes.

Explosion-protected lifts  Alimak introduces a new range of explosion-protected Ex lifts for offshore and petrochemical applications in hazardous areas. The new ALIMAK SE-Ex range complies with ATEX (Europe) and NEC (USA) regulations, offering capacities of between 400 kg and 1600 kg and has direct online motor control. The Ex range is available in 13 car sizes measuring between 0.91 m × 1.3 m and 1.56 m × 2.21 m. It travels at speeds of 0.4 – 0.6 m/s. Built to the same quality standards as the ALIMAK SE range, the new range features rack-and-pinion build so that in the event of a power failure, the car can slide back to the nearest landing at a controlled speed. If the rated speed is exceeded, the car is stopped smoothly and safely by an overspeed safety device.

|