|

|

|

By Petroleum Technology Transfer Council |

Hydraulic diaphragm electric submersible pump improves completion design, lowers lifting costs

Hydraulic diaphragm ESPs, used in place of conventional beam pumps in Kentucky strippers, have resulted in reduced well servicing and fewer days of lost output.

Bernie Miller, Bretagne LLC, Lexington, Kentucky, and Nicholas Boyaci, Smith Lift LLC, Houston

With conventional beam pumping units, Bretagne LLC (Bretagne) has experienced high failure rates in Kentucky oil wells, due to erosion and abrasion of pump components by sand production. Bretagne’s shallow wells (less than 1,500 ft) typically produce less than 20 bfpd. Bretagne has replaced a number of beam pumps with hydraulic diaphragm, electric submersible pumps (HDESPs) developed by Smith Lift. This article documents the details and economic benefits of two such installations.

The economic benefit on the first well resulted from reduced well servicing and fewer days of lost production. The second well features a faster, more economical way to deploy pumps. The HDESP pump is deployed on small, 1-in. diameter, flexible production tubing. Deployment on flexible production tubing is much faster than with conventional means. Higher velocities with smaller tubing help in dealing with solids settling.

The operator is moving forward with HDESPs deployed on flexible production tubing for their new drills, pumping system upgrades and wells to be placed back on production.

PROBLEM STATEMENT

Bretagne operates over 600 stripper oil wells in Kentucky. Many of these wells are located near rivers or in national forests, and the company operates with vigorous programs to prevent ecological damage. A number of Bretagne’s wells experience short beam pump run life, resulting from erosion and abrasion of pump components by sand contained in reservoir fluids. Maximizing run time between pulls is crucial to stripper economics and a key operator goal. In addition, environmental consciousness highlights the need for a quiet, leak-free, low-surface-profile pumping system that operates safely in unattended remote locations.

TECHNOLOGY SELECTION CRITERIA

A list of attributes required for a pumping system that meets Bretagne’s goals for efficiency and superior environmental safety when producing from marginal, shallow wells includes:

- Capable of utilizing the most efficient tubular design

- Less labor-intensive and can utilize coiled tubulars

- Capable of handling formation sand at low flowrates

- Cost-effective, corrosion-resistant materials

- Minimal system installation cost

- Minimal routine maintenance

- Reduced need for corrosion treatment of downhole tubulars

- Effective, inexpensive pump-off control

- Reduction in down time from historic levels

- Leak-free, low surface profile system, consistent with environmental sensitivity and safety in unmanned, remote locations.

After reviewing available technologies, Bretagne found that the HDESP best met its performance and environmental goals. The HDESP, manufactured by Smith Lift a division of Smith International, Inc, is designed for low production rates (<200 bfpd) in oil, gas and coalbed methane wells with depths shallower than 2,500 ft.

TECHNOLOGY/ OPERATING BENEFITS

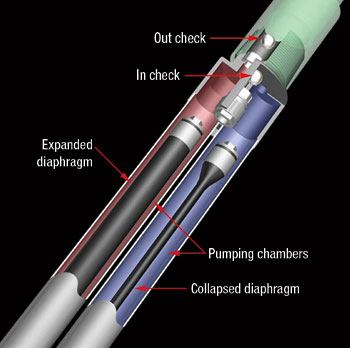

The pump is powered by a three-phase, triple-insulated electric motor. Two diaphragms positively displace formation fluids into the production tubing, Fig. 1.

Solids and rod wear. HDESP diaphragms completely isolate well fluids from the pumping mechanism. Pump features are not exposed to abrasive solids and sand particles that can interfere with the plunger-to-barrel interface in a beam pump. Since power is transmitted to the downhole motor by an ESP cable, mechanical erosion of rods and tubing wear is also eliminated.

Benefits for the environment. Fig. 2 illustrates the HDESP’s low surface profile. There is no potential for stuffing box leaks. Since there are no moving parts at the wellhead, safety to people and wildlife is significantly improved. As an added benefit, HDESP pumps are virtually silent.

|

Fig. 2. Wellhead installation.

|

|

Easy to install and operate. The HDESP comprises a single, integrated pump and motor. Unit length is less than 8 ft, and weight is less than 120 lb. Outside diameter, 3.75 in., allows deployment in casing with diameters of 4-1/2 in. or greater. As the HDESP has no moving parts on the surface, routine maintenance, such as lubrication and adjustments, is eliminated.

Pump-off control. Motor controllers that detect pump-off by measuring power consumption changes associated with dynamic fluid level are now available. As power consumed by the HDESP passes a low-power trip point during pump-off, the unit is shut down, and a restart timer is activated to automatically restart the pump after a programmed well recovery time. This feature eliminates the need to monitor pump-off with downhole sensors.

FIELD RESULTS FOR FLAHAVEN 1460

The North Flahaven 1460 well, located in a National Forest, was experiencing high failure rates with beam pumps – six times during a 12-month period – due to erosion/ abrasion of pump components. This well produces about 3 bopd from 1,200 ft. As the well is in a remote location, and there are restrictions on travel, it was down for 97 days in one year while awaiting pulling units.

An HDESP pump rated at 150 bpd, 3 hp, was installed and it ran for 326 days without problems of any kind before experiencing an electrical failure in its overload protection system. A redesigned motor controller now being used at other sites has significantly extended system run life. An HDESP with the new controller has been installed on this well and is now operational. In comparison to the prior beam pump, the HDESP pump’s run time was a six-fold improvement.

Economics. Based on improved annual production (326 days for the HDESP versus 268 days for the beam pump) from the North Flahaven 1460 well, the HDESP System improved cash flow by $8,700. For purposes of this comparison, production is valued at $50/bbl and 3 bopd. In addition, the pull frequency was reduced from 6 to 1, saving Bretagne $4,000 in pulling costs ($800/pull).

RESULTS, CAYWOOD JOHNSON 3P WELL

Bretagne deployed a second HDESP unit in the Caywood Johnson 3P well. This well was placed back on production, and it is part of a new enhanced recovery project area. In this 1,300-ft installation, which occurred in April 2006, the operator deployed an HDESP pump on 1-in. production tubing. The smaller-diameter tubing significantly increases produced fluid velocity; this greatly assists solids transport, Table 1.

| TABLE 1. Comparison of fixed flowrates, resulting velocities in 1.99-in. and 0.61-in. ID pipes |

|

|

An added benefit is that deployment was achieved by a single unit that both hauled the coiled production tubing (total weight less than 300 lb [0.23lb/ft x 1,200 ft]) to the site, and then ran the coiled production tubing, power cable and pump into the well, Fig. 3. This is much more efficient than rod pump installations that require a crew to haul, unload and pick up the rods and tubing to be run in the well, along with a separate pulling unit to install and retrieve the downhole pump and rods. A two-man crew can install the HDESP and flexible production tubing combination in 12 to 16 man-hours, compared to a three-man crew spending from 36 to 54 man-hours for rod pump installations.

|

Fig. 3. Installation of pump and plastic tubing.

|

|

FUTURE PLANS

Bretagne views this type of system to be the pumping solution for the future. In view of the HDESP system’s performance in the areas of well completion cost, run life, installation costs, production tubing design and environmental protection costs, the company has decided to move forward with the HDESP and flexible production tubing combination. This system is planned on new drills, pumping system upgrades and wells to be placed back on production.

ACKNOWLEDGEMENTS

The authors thank Virginia Lazenby, chairman, Bretagne LLC, and Danny Wilson, operations manager, Bretagne LLC, for their contributions in the successful implementation of a new technology, and for their support and cooperation on this article.

THE AUTHORS

|

|

Bernie Miller is a consulting engineer to Bretagne LLC. He graduated from West Virginia University with a BS degree in petroleum engineering, and from Tulane University with an MBA degree. Mr. Miller is principal consultant for Miller Energy Technologies LLC and has worked for Gulf Oil Corp., Omni Exploration, TransAtlantic Exploration and Bretagne. E-mail: 0020berniem@millerenergytech.com

|

|

|

Nicholas P. Boyaci is the general manager of Smith Lift. He holds a BS degree in petroleum engineering and an MBA degree from the University of Tulsa. E-mail: nboyaci@smith.com

|

| |

|

|