Advances in Drill Pipe

Aluminum alloy tubulars for the oil and gas industry

Russian experience demonstrates a new choice for drilling challenging wells.

Mikhail Y. Gelfgat and Vladimir S. Basovich, Aquatic Company; Alex Adelman, Drilling Research and Development Corp.

The oil and gas industry requires significant tubular goods. Drill pipe, casing, tubing and risers must be designed and manufactured to accommodate present and future expectations of drilling deeper, longer, faster and more efficiently, while maximizing production for every well drilled.

For years Aluminum Alloys (AA) have been widely used as construction materials in the aerospace, automotive, marine and civil construction industries. Unfortunately, AA tubulars use in the petroleum industry has been rare. Aluminum Drill Pipe (ADP) was used extensively only in the Former Soviet Union (FSU).

OILFIELD USE

The first research work and experiments with ADP began in the second half of the 1950s with encouraging field results. In following years, ADP was more widespread in directional well drilling, combined with turbodrills and electrodrills. Wide use of ADP reduced hoisting loads substantially, reduced trip time, lowered borehole hydraulic losses, reduced mud pump loads, and lowered transportation costs. In addition, ADP produced positive rotary drilling developments.1,2 Also, primarily in the FSU, oil country tubular goods (OCTG) were made of AA including tubing, workover pipe and casing.3

During the last decade, studies of light metal alloys for the oil and gas industry became essential, because of the importance of structure weight in offshore exploration and development. Constructing AA helicopter deck and quarters became common practice. Similarly, the extension of wells’ measured depth required new drillstring and long casing design.

For most tubular applications, pipe strength properties must be highly rated to withstand the pipe’s weight as well as operational loads. For drillstring or riser, the weight component could be 90% of operational loads. Any structural weight reduction significantly benefits the overall design and performance of a single well, well cluster or platform.

In the early 1990s, engineers considered titanium as a possible construction material, first for the marine riser and later for drill pipe. At the same time, the authors applied ADP in offshore stratigraphic and scientific projects. The experience gained led to AA as potential drilling riser material. AA drilling riser is now used offshore Brazil and the Gulf of Mexico with aluminum tubing and line pipe in the field testing phase.

The specific material strength (strength-to-weight ratio) was the key advantage of AA tubulars over titanium and steel products, about twice that of steel (Table 1). Other unique physical and mechanical properties of AA include corrosion resistance and manufacturing workability. AA extruded tubes and pipe up to 3 ft (900 mm) in diameter and more than 11D2-in. wall thickness can be produced. Today, ADP is widely used in onshore directional drilling.

| TABLE 1. Mechanical properties of drill pipe materials. |

|

|

AA tubulars in use include drill pipe, bottom-hole assembly (BHA) components, non-magnetic drill collars and MWD housings, tubing, and drilling riser. AA tubular goods under development consideration includes production and completion risers, landing strings and casing.

ADP WITH STEEL

ISO 15546 determines the standard for ADP with a steel tool joint. ADP should be used in the same manner as steel drill pipe, which is why steel tool joints are needed with aluminum pipe bodies. Steel tool joints extend the connection’s service life – steel threads can withstand three times the make-ups of aluminum threads. Furthermore, steel thread with an aluminum pipe body weighs considerably less than corresponding steel joints and pipe, which reduces connection wear.

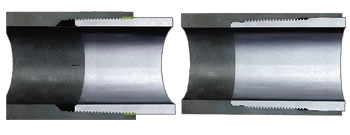

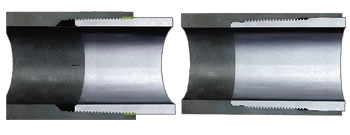

The main feature of steel-jointed AA pipe is the second thread cut into the box and pin, and it specifies the ADP type. ISO 15546 accepts only a threaded connection with a stabilizing shoulder. For many years, simpler designs were used with reasonable success when drilling with downhole motors and limited drillstring rotation, Fig. 1.

|

Fig. 1. For many years, simple aluminum drill pipe designs were used with reasonable success (left). ISO 15546 requires a threaded connection with stabilizing shoulder (right).

|

|

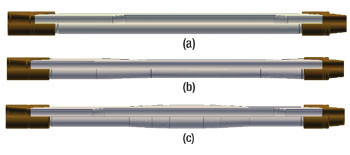

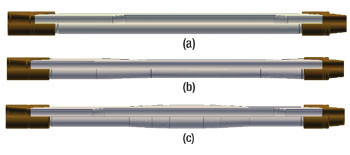

ADP features external or internal upset ends for tool joint connection and handling. Pipe body wall thickness is varied for the same connection type, Fig. 2. Light Alloy Improved Dependability Drill Pipe (LAIDP) can be made with protective thickening in the middle of the pipe, and made along with the entire pipe extrusion. Such protection prevents pipe body wear from rotation and centers the pipe in a borehole, increasing critical buckling load.

|

Fig. 2. LAIDP typical designs include (a) LAIDP 147x11 with internal upsets, (b) LAIDP 131x13 with external upset and (c) LAIDP 147x11P with internal upset and protection thickening.

|

|

Heavy-wall LAIDP (HWLAIDP) has an aluminum body wall thickness equal to the pipe thickness in the upset area, or even more in some cases. HWLAIDP is used as a transition from regular LAIDP of the same size and the BHA at the bottom, or steel pipe at the top of the drillstring. Landing string can be designed similar to HWLAIDP for maximum loading capacity, Fig. 3.

|

Fig. 3. Heavy-wall LAIDP has a wall thickness equal to the pipe thickness in the upset, as in this 7-in. prototype for a 1,200 kips landing string.

|

|

INTEGRAL JOINT ALUMINUM TUBES

The ability to extrude aluminum tubes with upset ends provides an excellent opportunity to cut threads directly in the extruded product. This allows integral-joint ADP to be designed for different functions, as well as tubing, casing, line pipes without couplings, and production or completion risers, Fig. 4.

|

Fig. 4. The ability to extrude aluminum tubes with upset ends allows integral-joint, aluminum drill pipe to be designed for different functions.

|

|

In case of drilling problems, these pipes can be easily milled, so that the fishing job can be done with the released part of the string. For BHA weight reduction and to lower the drag while drilling horizontally, steel non-magnetic drill collars can be replaced by thick-wall, integral-tool-joint ADP with high magnetic permeability.

DRILLING RISER

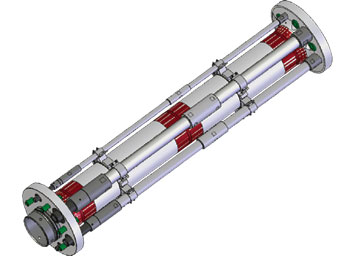

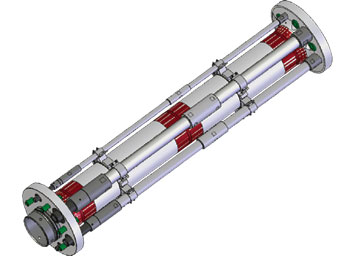

The aluminum drilling riser concept follows standard drilling riser design. The main thick-wall tube is 21-in. OD with welded connections on each end, usually flanges. The kill and choke, booster and hydraulic lines surround the main tube with connections in the flanges and are supported by clamps, Fig. 5.4

|

Fig. 5. Aluminum drilling riser design uses a thick-wall main tube surrounded with kill and choke, booster and hydraulic lines supported by clamps.

|

|

Existing equipment allows the extrusion of 36-ft (11-m) tubes with up to 22.4-in. (570-mm) OD and 1.2-in (30-mm) to 1.4-in. (35-mm) wall thickness. Extruded tubes for service lines are 36-ft (11-m) long, requiring a threaded connection in the center of each line. Aluminum pins and boxes are under development. All service lines have a telescopic unit to relieve tensile stresses.

Service lines are connected to the main tube using aluminum welded clamp bands, but different clamp designs, including plastics are under consideration. Clamps are needed to prevent the service lines from buckling, to block buoyancy module displacement and to provide support for corrosion protection units.

LAIDP IN RUSSIA

Initial production of LAIDP began in 1998 at Aquatic Co.’s experimental plant. LAIDP production was based on design and production of similar pipe at Scientific Production Center “Kolskaya Sverkhglubokaya” (Kola super-deep). This pipe was successfully used while drilling in extreme loading conditions on the Kolskaya SG-3, Uralskaya SG-4, Krivorozhskaya SG-8 and other ultra-deep wells.

In 2003, LAIDP was run through acceptance testing in Slavneft wells, where it obtained approval and was recommended for serial production. In 2005, an additional specialized pipe production shop was commissioned at Serov Mechanical Plant, Fig. 6.

|

Fig. 6. The Serov Mechanical plant assembles steel tool joint – aluminum pipe, (top left).

|

|

During the last few years, the production of LAIDP exceeded 100,000 m, including almost 10,000 m for deepwater geotechnical and horizontal wells in international markets. The majority of LAIDP produced has been used to drill directional and horizontal wells in West Siberia. A typical drillstring assembly to drill inclined well section includes: BHA (drill bit, motor, MWD, stabilizers, etc.); drill collars, 164 – 197 ft (50 – 60 m) of HWLAIDP for gradual stiffness transfer to LAIDP, standard LAIDP and 656 – 984 ft (200 – 300 m) of steel drill pipe.

The mean life of one LAIDP set 656 – 820 ft (200 – 250 m) is about 164,041 ft (50,000 m) using the combined drilling method with 400 – 450 tool joint make-ups. Some pipe sets performed up to 295,275 ft (90,000 m) with 550 tool joint make-ups. This is superior to steel pipe in similar applications and can be attributed to reduced weight.

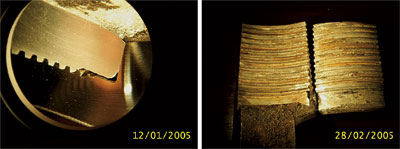

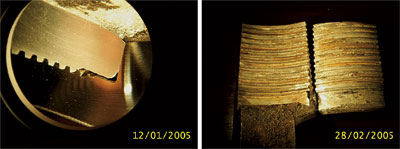

While the LAIDP is in use, there is abrasive wear along the pipe body and across the steel tool joint. Pipe used to drill directional and vertical well sections experience wear across the tool joint diameter, and the pipe used to drill horizontal sections is worn mostly along the main pipe surface.

Wear has a one-sided pattern, caused by rotating the string at 40 – 60 rpm using combined drilling methods, when the string rotation axis is not aligned with the well axis. However, even in the these drilling conditions, the wear of both LAIDP and tool joints was not more than 10% of the rated thickness and the pipe load capacity rating was not affected. Hydro-abrasive wear inside the pipe was not observed.

The largest amount of 5.8-in. x 0.4-in. (147-mm x 11-mm) LAIDP manufactured from D16T alloy was used by the Slavneft subsidiary Megionneftegaz to drill directional and horizontal wells using combined drilling methods and polymer drilling mud with 1.14 – 1.20 density and 8.0 – 10.0 pH. Inspection, performed this year for pipe in use since 2000, showed neither surface corrosion damages nor electromechanical corrosion where the aluminum and steel touch.

Throughout the entire history of LAIDP use, three instances of LAIDP failure occurred. Megionneftegaz experienced two failures of the main pipe body when the drillstring became stuck. The pulling force used to free the pipe exceeded the tensile strength by 15 – 20%. Another failure occurred recently across the API thread of the steel tool joint pin. The failure cause is still under investigation and the tool joint’s material analysis is being evaluated.

EXENDED REACH DRILLING

There was field experience using LAIDP while extended reach drilling (ERD) a Petrobras well in northern Brazil. The S-106 well was drilled from the shore to the shallow offshore oil field.1 Well design contributed to the well’s drilling complexity, with the vertical part extending for only 1,968 ft (600 m), and used a short radius to built angle.

Starting from TMD of 2,893 ft (800 m), the borehole had 83° inclination. Using LAIDP both in the horizontal section, and partially in the built-up zone, it provided WOB transfer without loss of drillstring stability and permitted drilling to the target. This was accomplished due to LAIDP’s strength-to-weight ratio advantage; its lighter weight resulted in reduced loads and drag forces. While drilling the lower intervals, there was considerable hydrogen sulfide, up to 6% in the mud. The LAIDP became covered with a protective black oxide film, but no H2S corrosion damage occurred.

After drilling the well, the entire drill pipe set was stored in Mossoro, Brazil. Eventually, several joints were transferred to CENPES, Petrobras’ research center, for material and pipe fatigue analysis. Small and full scale samples were studied. The result of that work was published in 2004 with a generally positive conclusion about high strength AA use in ERD.5

A few of the HWLAIDP experienced surface layer corrosion. The survey revealed that corrosion was from inadequate pipe maintenance after well completion. Mud and cement slurry were not completely removed after the pipe was pulled out of the hole and before it was covered with a protective dope. No serious corrosion damage occurred in the steel-to-aluminum thread connection, Fig. 7.

|

Fig. 7. The steel tool joint – aluminum pipe connection looks good after drilling the SC-106 well and two years in storage (left half of right image).

|

|

The known problems in ERD with steel pipe, torque and drag, presented designers with a challenge: to decrease the specific weight of a single joint. One possibility is to increase the pipe length. With the standard drill stand length at 90 ft, using two 45-ft joints seems superior to three 30-ft joints. This saves the weight of one tool joint along with the extra upset of one pipe. The tool joint design itself features an extra long thread and extra body length necessary for hardbanding.

The total length of a steel tool joint can be more than 1.5 ft. A similar approach with aluminum pipe would be counterproductive. Russian drilling practice uses 36-m (118-ft) or 24-m (79-ft) stand length, therefore pipe of 12-m (39.4-ft) length are used. For the western-type rigs, 30-ft (9-m) pipe was produced as well.

Thus, for ERD we recommend 30-ft LAIDP with protective middle thickening. This achieves a decrease of the string weight and critical buckling loads. The torque and drag analysis for LAIDP of this design looks superior to steel pipes and for pressing forces. The limited experience available now with extra long 44-ft (13.5-m) experimental alloy LAIDP with a protective middle pad has shown that our concerns about their use are legitimate.

This pipe was field tested in a deep, directional well drilled through complex geologic in very hard and abrasive rock. The well was drilled using combined drilling method, rotating the drillstring at 120 rpm. Considering that pipe with a 44,291-ft (13,500-m) length has little lateral rigidity, it bent at the rotation speed and came in contact with the borehole wall. Practically the entire pressing load was shifted to the protective pad. This load wore the pad to 5.9-in. (150-mm) OD from an initial 6.8-in. (172-mm) OD, and necessitated taking the pipe out of service.

Analysis of LAIDP in wells with up to 15-km length has shown positive results. Actually, AA drill pipe is the only solution for the wells of such length, Table 2 and Fig. 8.

|

| Table 2 |

|

Drillstring assembly designed to drill 15,000-m, 8½-in. extended reach well

Click image for enlarged view |

|

|

|

Fig. 8. Aluminum alloy drill pipe is the only solution for a 15-km long extended reach well (see Table 2).

|

|

CONCLUSION

The FSU has successfully used ADP from the early 1960s. Recently developed LAIDP is suitable for up-to-date horizontal and multilateral wells drilling. The main advantage of AA when compared with steel is its light weight, and more specifically its weight-to-strength ratio. AA also has a clear advantage because of its non-magnetism and reduced modulus of elasticity.

LAIDP enables the industry to:

- Drill extended-reach wells with reduced cost and to longer distances

- Use lighter capacity rigs for deep-well drilling

- Use smaller rigs for drilling in remote or environmentally sensitive areas

- Save money on transportation

- Improve overall drilling performance in horizontal, deep-vertical and extended reach wells

- Enhance dynamic characteristics of BHA and non-magnetic BHA components.

Experience shows that as long as pH levels in mud and other media are controlled, and recommended operating and storage regulations are adhered to, any corrosion damage will not be a critical factor in the pipe’s service life. Drilling with LAIDP requires less power consumption due to reduced drillstring weight.

This paper discusses a small step our industry can take to meet our responsibility to drill wells deeper and longer, safer, more effectively and more economically. It is also about future vision and choice. For too long the drilling industry has been too conservative, failing to take calculated risks that are becoming all too necessary today.

Aluminum alloy tubulars are supported by careful engineering analysis and decades of field experience. Often, they are a competitive alternative to more traditional products. At times, they provide us with the only correct technical and commercial selection. They provide us with a real choice.

ACKNOWLEDGEMENT

The authors thank Petrobras and Slavneft representatives who provided important data. Thanks also to Aquatic Co.’s staff in the paper’s preparation. This article was prepared from SPE 97035, which was presented at the SPE annual convention in Dallas, Texas, October 9-12, 2005, and is published with permission.

LITERATURE CITED

1 Gelfgat, Mikhail Y., Vladimir S. Basovich, Vadim S. Tikhonov, “Drillstring with aluminum alloy pipes design and practices,” SPE 79873 presented at SPE/ IADC conference, Amsterdam, The Netherlands, 2003.

2 Gelfgat, Y. A., M. Y. Gelfgat, Y.S. Lopatin, Advanced Drilling Solutions: Lessons from FSU, Vol. 2, PennWell, 2003.

3 Fine, G.M., A.S. Neimark, Design and Operations of Drillstrings in Deep Wells, Nedra Publishing, Moscow, 1985.

4 Gelfgat M., N. Grebtsov, A. Podrazhansky, B. Vygodsky and V. Tikhonov, V. Shaposhnikov, V. Chizhikov, “High-strength aluminum alloys for deepwater riser applications,” OTC 16185 presented at Offshore Technology Conference, Houston, Texas, May 2004.

5 J. C. R. Placido, T.A. Netto, G.F. Miscow et. al., “Fatigue analysis of aluminum drill pipes,” ABM 2004-4029 presented at the 59th Annual ABM International Congress, San Paolo, Brazil, July 2004.

|

THE AUTHORS

|

|

Mikhail Y. Gelfgat is president and CEO of Aquatic Co. He has served the oil and gas industry in a number of distinguished positions, including laboratory head for the Drilling Research Institute (VNIIBT) for about 30 years. Dr. Gelfgat authored Advanced Drilling Solutions - Lessons from FSU and more than 50 technical papers. He earned an MS in mechanical engineering from Bauman Technical University in 1965 and PhD in Technical Sciences from VNIIBT in 1980.

|

|

|

Vladimir S. Basovich has been chief engineer of Aquatic Co. since 1997 and has over 45 years experience in the oil and gas industry. Before joining Aquatic, Basovich held senior management positions for the Kola ultra-deep borehole project. Dr. Basovich is the author of 50 publications and patents. He earned an MS in drilling engineering from Moscow Oil and Gas University in 1961 and a PhD in Technical Sciences from Drilling Research Institute (VNIIBT) in 1983.

|

|

| |

Alex Adelman is vice president of Drilling Research & Development Corp., Houston and has held staff and management positions in the oil and gas industry since 1978. Mr. Adelman is a member of SPE, participated in publication of Advanced Drilling Solutions - Lessons from FSU, and has extensive knowledge of the Russian energy sector. He earned a BS in mathematics and physics from SFA State University.

|

|

|