Drilling Fluids

Fluid weighting material yields low ECD while reducing sag tendencies

This material keeps fluids thin yet reduces sag, thereby enabling drilling in narrow pressure windows.

Dave Marshall, Baker Hughes INTEQ; Todd Franks, Shell UK Ltd.; and Cor Oldenziel, Elkem ASA

As producing zones mature, drilling can become increasingly difficult as the difference between pore pressure and fracture pressure decreases. Mud densities required to maintain shale stability can be very close to the pressure required to fracture depleted reservoirs. Such situations require special drilling fluids with low equivalent circulating densities (ECD), since the effective density increase due to the additional circulating pressure can, in conventional fluids, be higher than the margin between pore and fracture pressures. Furthermore, drilling in mature fields is often severely cost-constrained, causing some operators to try small holes and techniques such as coiled tubing drilling (CTD) and through-tubing rotary drilling (TTRD). All of these techniques increase the importance of drilling fluid design, as the small borehole sizes employed are likely to further increase ECD-related problems. Thinner fluids are more prone to material sag, and sag itself can be more critical in small hole sizes due to very narrow annular clearances.

SAG

During the past decade, much research has been conducted into the phenomenon of barite sag. There is now a widely accepted view that the magnitude of the low shear – below 1s–1 – viscosity of the fluid is a key parameter in differentiating between fluids that exhibit sag and fluids that do not. As the vast majority of drilling fluids are weighted with barite, most of the research in the area of sag has focused on muds containing barite. A number of products have appeared on the market that help improve a mud's sag resistance by altering the rheological profile of the fluid. In addition, drilling practices have been amended in some cases to avoid conditions where barite sag is most likely to occur – long periods of exposure of the drilling fluid to low shear, thinning of the mud prior to running casing, to name but two.

Changing the weighting material in a drilling fluid is a relatively radical step that requires additional work in the area of logistics to avoid cross-contamination and, in some cases, set up duplicate storages facilities. It also affects cost, since very few bulk-weighting agents are as cheap as barite. Most mud companies maintain significant stocks of oil-based mud in areas where it is widely used, and these stocks normally consist entirely of barite-weighted fluids. These stocks would have to be set aside and new mud built if a different weighting material was used.

ALTERNATIVE WEIGHT MATERIAL

Despite these additional requirements, the potential costs of a barite sag incident (rig time to recondition the fluid as a minimum, and loss of the hole in the worst case) mean that in wells where barite sag is assigned a high risk factor, the use of alternative weight materials is economically sound. As part of a long-term project to improve the resistance of drilling fluids to sag, Baker Hughes INTEQ has developed an invert drilling fluid using the proprietary weight material, Micromax – completely eliminating barite from the system.

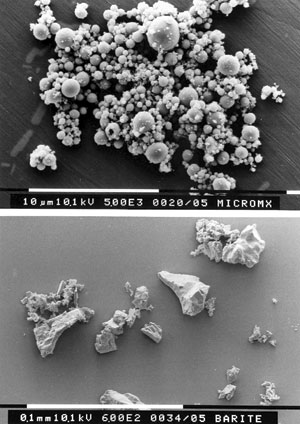

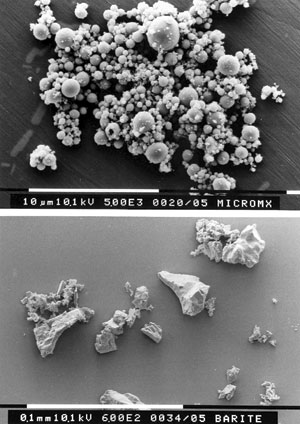

The alternative weight material is manganese tetraoxide and is supplied as a fine red/brown powder. A comparison of its key physical properties with barite is shown in Table 1. Comparative photographs are in Fig. 1.

| |

Table 1. Comparison of physical properties. |

|

| |

Property |

Barite |

Micromax |

|

|

|

|

| |

Density (g/cm3) |

4.2 |

4.8 |

|

| |

Mean particle diameter (µm) |

15–20 |

0.5 |

|

| |

Hardness (Moh’s scale) |

3.0–3.5 |

5.0–5.5 |

|

| |

Abrasivity (relative scale) |

1 |

0.3 |

|

| |

Shape |

Angular |

Spherical |

|

|

|

Fig. 1. Differences in size and shape between the two materials. Note that the magnification on the Micromax photograph (top) is 10 times greater than on the barite photograph (bottom).

|

|

The very small size and spherical shape of manganese tetraoxide particles result in desirable properties when used in place of barite. Plastic viscosities are greatly reduced due to the lower inter-particle friction as a consequence of the spherical shape. Although the particles are more dense than barite particles, their much smaller size means that they can be supported by weaker structures within the fluid and this means that lower yield points can be run without increasing the risk of sag. This effect is illustrated in Table 2 in which three mineral oil-based muds with the same density are compared. Muds A and B have about the same yield point, yet mud B has a plastic viscosity approximately half that of mud A. Mud C has the same degree of sag resistance as mud A and shows an even greater reduction in plastic viscosity compared to mud A, as well as a 50% reduction in yield point compared to mud B.

| |

Table 2. Comparison of equal-density muds. |

|

| |

Property |

Mud A |

Mud B |

Mud C |

|

|

|

|

| |

Density, ppg |

11.7 |

11.7 |

11.7 |

|

| |

Oil:water ratio |

80:20 |

80:20 |

80:20 |

|

| |

Weighting material |

Barite |

Micromax |

Micromax |

|

| |

Plastic viscosity, cP |

35 |

18 |

13 |

|

| |

Yield point, lb/100ft2 |

20 |

19 |

9 |

|

| |

Gels, lb/100ft2 |

14/22 |

10/16 |

5/8 |

|

|

FIELD APPLICATION

The ability of this alternative weighting material to provide muds with superior rheological profiles and greatly reduced sag tendencies is expected to have two primary field applications: HT/HP drilling and slim-hole drilling. For HT/HP applications, the reduced sag tendency, combined with much reduced plastic viscosities, will be of great value in avoiding downtime due to mud conditioning and preventing rigs from having to operate at or near hydraulic limits. Such fluids would also be less likely to result in downhole losses and the often-considerable cost of lost circulation events would be mitigated. Rheological profiles become proportionately more important in small hole sizes. The increase in recent years in CTD and TTRD provides further potential market for this weighting material.

What is believed to be the first application of oil-based mud weighted solely with the proprietary manganese tetraoxide occurred in 2003, when such a fluid was used by Shell to drill a series of five TTRD sidetracks from the North Cormorant platform in the northern North Sea. TTRD was chosen for economic reasons; the small reserves being targeted did not warrant the cost of drilling conventional sidetracks. The main technical limitation from a drilling fluid perspective was caused by the very narrow margin between pore pressure and fracture pressure (less than 2 lb/gal in some cases). For some of the planned wells, preliminary hydraulic modelling suggested that the 4-1/8-in. sections could not be drilled with a barite-weighted mud of sufficient viscosity to avoid problems related to barite sag.

Conversely, the manganese-tetraoxide weighted muds were determined to be capable of drilling all the planned wells, although viscosities would still need to be kept as low as possible. All the wells were deviated and the potential for sag was a major concern. The ability to allow thin fluids to be formulated without increasing the risk of sag was a critical parameter in the fluid selection process.

The fine particle size and high potential for dust creation would have been a concern from a health and safety perspective (inhalation issues), but this problem was avoided by supplying the weighting material pre-mixed in the mud. Kill-weight mud was shipped to the rig and a portion of this was diluted back with oil and brine to the required drilling weight. This proved to be a trouble-free operation and greatly simplified the logistics associated with working with a non-standard weighting material.

FIELD RESULTS

Five wells were drilled using the new mud. A summary of well details is provided in Table 3.

| |

Table 3. Summary results from five wells. |

|

| |

Well

name |

Mud

density |

Hole

angle |

Hole

size, in. |

Measured

depth at TD |

Frac

pressure |

|

|

|

|

| |

CN 24 s2 |

13.2 ppg |

64° |

4-/2 |

15,311 ft |

15.6 ppg |

|

| |

CN 18 s6 |

13.7 ppg |

66° |

4-1/8 |

11,913 ft |

15.5 ppg |

|

| |

CN 14 s2 |

13.7 ppg |

38° |

4-1/8 |

10,538 ft |

15.4 ppg |

|

| |

CN 32 s4 |

12.5 ppg |

78° |

4-1/8 |

14,481 ft |

15.5 ppg |

|

| |

CN 24 s3 |

13.3 ppg |

60° |

4-1/2 |

15,115 ft |

15.6 ppg |

|

|

Laboratory work conducted prior to the mud system being used in the field had suggested that the lowest yield point which could be safely run without the risk of sag under typical conditions was in the range 8 – 10 lb/ 100 ft2. This was confirmed in the field with yield points run in the 8 – 12 lb/ 100 ft2 range throughout most of the drilling and no sag incidents. The only incidence of mud density variations resulting from sag was on the first well (CN 24 s2), where mud was left in the hole for about 36 hours while a whipstock was set. Returns from the well varied in density from 12.9 to 14.4 lb/gal, with a yield point of 5 lb/100 ft2. A minor treatment of the system with organophilic clay brought the yield point up to 8 lb/100 ft2, and no further sag problems were encountered. On the third well (CN 14 s2), it was noted that there was no density variation at all in the mud circulated out of the hole after running the liner; this mud has a yield point of 9 lb/100 ft2.

CONCLUSION

Although Micromax has been widely used as an additive for oilfield cementing for many years, there have been few drilling fluids applications. This material has proven to be valuable as a mud weighting agent when low plastic viscosities and high resistance to sag are required. The approach taken to minimize health and safety concerns from dust was successful, and the trouble-free drilling (from a mud perspective) of five TTRD wells vindicated the selection of the mud system used. Properties in the field were very close to those predicted from the planning work.

ACKNOWLEDGEMENTS

All drilling operations require a coordinated team to ensure success, and we thank all those involved, both onshore and offshore, with the execution of these wells for their support during this work, as well as numerous others in Baker Hughes INTEQ, Shell U.K. Ltd and Elkem ASA for their help and assistance. We are also grateful to Shell, Baker Hughes INTEQ and Elkem ASA for permission to publish this paper.

THE AUTHORS

|

|

Dave Marshall graduated from Aberdeen University with a PhD in organic chemistry and joined Milchem Drilling Fluids in 1984. He has worked in a variety of laboratory, technical and operational positions for Baker Hughes since then. He is the region technical manager for Baker Hughes INTEQ based in Aberdeen.

|

|

Todd Franks started working in the oil field in 1990 as a cementer. He progressed through the ranks to become a coiled tubing drilling engineer, expanding into slimhole drilling. He is currently a well engineer with Shell U.K. Ltd on the Technology Team for the European Region helping to implement through tubing drilling.

|

|

Cor Oldenziel earned an MSc from Delft University of Technology in 1997. After graduation, he worked in the salt solution mining industry constructing new wells. For the last three years, he worked for Elkem ASA, Materials, and has recently been transferred to Dubai to focus on business development in the Middle East and Southeast Asia. He is presently business manager, Well Drilling Products of Elkem ASA, Materials.

|

|