Expandable technology and application growth continues

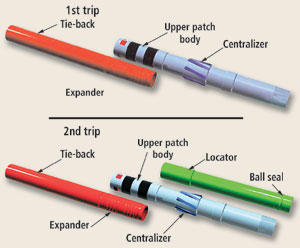

Oil Country Tubular GoodsExpandable technology and application growth continuesSix companies review recent innovations or further system development of downhole expandable tools.Perry A. Fischer, Editor, and Robert E. Snyder, Executive Engineering Editor In July 2003, World Oil compiled contributions of the principal suppliers of tools and technologies for applying the concept of expanding downhole tubulars, screens and other related equipment to enhance the well completion process by reducing time/ costs and, in many cases, significantly improving well productivity. That editorial feature was organized into three phases: 1) Status of expandable technology; 2) Technologies in testing or development; and 3) What's in the future. In this follow-up article, World Oil continues its report on expandables by focusing on what industry has done to add to the “status” of mid-2003, with new, marketable expandable technologies. Six companies have submitted data on new tools, and significant developments of existing systems that have altered the status of one year ago. Described here are the recent contributions of: TIW, Baker Oil Tools, READ Well Services, Enventure, Halliburton and Weatherford. A separate, related article in this Oil Country Tubular Goods section offers a report on the evolution and status of the five-year-old Monodiameter well concept – what it offers industry and where it is in the process. TIW Expandable casing patch. The 2T XPatch system is an expandable casing patch that enables the operator to use conventional tubulars with any length of casing. This company's new system has many different applications, owing to its design, Fig. 1. The tool is a two-trip system that is hydraulically set with conventional surface pumps and can be run in any type of wellbore, including high-angle, horizontal, monobore or slimhole. Run-in sizes range from 2-3/8 -in. to 5.5-in., while expanded sizes range between 3.5-in. to 7-in., respectively. The tool comprises a Lower and Upper Patch system, Fig. 2. Conventional tie-back capabilities allow the Lower Patch to be run simply as a liner if desired. The system can then be tied back with a seal nipple as a full-string tie-back to the surface or as a “stubtie tie-back” when run with the Upper Patch. The Upper Patch also has tie-back capabilities that allow multiple patches to be run and stacked as desired.

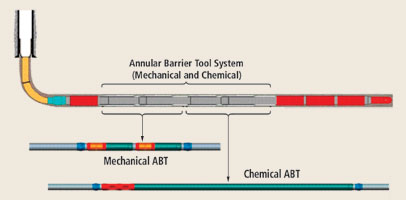

For sealing and expanding, the tool has a centralizer ball seal expander. Using elastomer seals and expandable metal technology, the new patch system design employs TIW's Metal-to-Metal Ball Seal Mandrels that not only expand the patch but provide a permanent leak-proof seal across corroded sections of pipe, perforations or any other type of leaks the operator wishes to isolate in the wellbore. Pressure integrity of the patch equals that of the liner run. A detailed 29-step procedure is available online at: http://www.tiwtools.com/2tflyers/2T%20Xpatch%20Flyer.pdf. ENVENTURE Solid Expandable Tubular (SET)* Technology has come a long way in its five years of commercialization. With over 250 jobs installed and 55+ mi of tubulars expanded, the market continues to grow at a rapid pace. A paradigm shift occurred in the past year as more customers realize the benefits of planning the systems into the original well design. A major operator in the Far East utilized the technology in conjunction with surface stack drilling to maintain hole size at TD. Today, it is common practice to plan solid expandables in surface-stack applications to drill in ultra-deep water without compromising hole size. Openhole Liner. In May of 2003, Kerr-McGee installed the first Openhole Liner (OHL)* System through a window exit. The system's sidetracking capabilities allow operators to rethink their existing redevelopment plans. To date, nine systems have been installed through window exits and three through milled sections. A major operator in the Middle East recently signed a contract to use SET systems to remediate over 40 wells. By sidetracking and installing solid expandable tubulars, operators gain access to previously unobtainable payzones. Surface-stack drilling and sidetracking are just two of the new expandable technology applications that operators are planning into their well designs on a regular basis. This transition from contingency to planned-in usage of the technology marks the progress of the solid expandables market. HALLIBURTON Halliburton now offers several additions to its PoroFlex* System and the VersaFlex* System. A significant enhancement to the first system is addition of the Annular Barrier Tool System. PoroFlex expandable screen completion system. This technology has been enhanced with several additions. At the time the July 2003 article was written, Halliburton was in the process of developing a corrosion-resistant alloy (CRA) version; this is now available. The CRA version is constructed from 316L stainless steel base pipe with either 316L or Alloy 20 screen. Slow strain rate testing has confirmed the safe operating environment of 316L stainless in varying concentrations of H2S and CO2 at elevated temperatures. Within this operating envelope, 316L stainless provides desirable pre- and post-expansion mechanical properties roughly equivalent to those of 13Cr. The company has also added innovative Annular Barrier Tools (ABTs) to the system. These ABTs are available in various configurations, but all share the common feature of having uniform base pipe expansion, thereby providing a flush ID throughout the interval covered by the system, which maintains a higher collapse rating. The fixed-reach tool provides a set amount of expansion and is used when an operator requires annular isolation within a gauge or nearly gauge borehole. The variable-reach tool provides sealing capabilities in holes with variable diameters. Two versions of the variable-reach tool are available – a mechanical and a chemical configuration, Fig. 3. The mechanical version provides reliable openhole isolation by deploying a compliant cylinder against the rock face. The chemical variable-reach tool combines the functionality of the mechanical variable-reach tool with a chemical seal that works to seal off the intervals adjacent to the tool. The various ABTs can be run individually or in combination with each other in the same system.

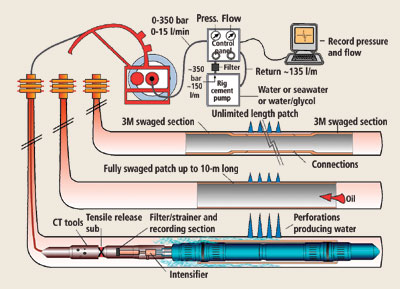

Halliburton's original PoroFlex system utilizes a two-trip expansion method that allows the operator to circulate through the system while running it into the hole. A single-trip system, in the final test phase, reduces installation time and system complexity. Also developed is a retrievable internal isolation packer that, when combined with the annular barrier tools described above, allows operators to deploy cased-hole functionality in an openhole completion – a truly expandable completion. Additional system enhancements are ongoing, including a variable expansion cone to reduce the time required to expand the completion interval and identification of critical-service CRA metallurgy suitable for use, particularly, in injection wells. The PoroFlex system continues to maintain high reliability, with zero failures of base pipe, screen or connection, and no reported sand production in any installations to date. VersaFlex expandable liner system. This Halliburton system continues to perform well in the expandable liner hanger market, and several enhancements to the product line are working to maintain that lead. The company had six sizes available at the time of this writing – 5-in. x 7-in., 5-1/2 -in. x 7-in., 7-in. x 9-5/8 -in., 7-5/8 -in. x 9-5/8 -in., 9-5/8 -in. x 11-3/4 -in. and 11-3/4 -in. x 13-3/8 -in. – and it was working on an additional three sizes. All of the company's systems have been qualified to ISO VO standards. And a corrosion-resistant alloy system is in development and is scheduled for commercial availability by year-end. Installations have exceeded 30 jobs, with liner lengths from 160 ft to 6,000 ft, while maintaining a record of no pre-setting, 100% liner-top pressure integrity, and no instances of trouble entering the liner top to drill the next interval. READ WELL SERVICES The HETS* system developed by UK-based READ Well Services uses directly applied hydraulic pressures in excess of 20,000 psi to permanently expand components into the well architecture. Particular advantages of this technique are the single-trip deployment and compliant expansion offered. TieBack system. The system's TieBack is a casing patch/ tie-back solution developed in 2002 and now qualified for casings up to 14 in., with strength up to P110. The challenge is to extend the operation of the system for deepwater wells – where it will have to operate below at least 1,000 m (3,280 ft) – and for stronger casings like Q125. This scenario requires expansion pressures well above 30,000 psi using heavy-duty versions of the downhole intensifier developed for the liner patching system, and it is in development. Liner Patch. While a number of other applications for the system are still “under wraps,” the Liner Patch is now in field trial with a North Sea major, and will be commercially available toward the end of 2004. While the TieBack offers a means of joining two casings downhole, the Patch is an internal cladding system for repair and sealing purposes, or perforation shut-off. Because HETS is able to successfully expand most metals, this internal cladding system is typically constructed from 316 stainless steel rather than softer alloys. This makes the patch extremely long-lived in the downhole environment. The metal-to-metal sealing capability complements the durability of the steel, because there are no elastomeric seals to degrade. The illustration, Fig. 4, of a patch deployment highlights its operational flexibility. Shown deployed on coiled tubing, it can also be run on drill pipe, and will eventually be available as a wireline system.

One criticism sometimes leveled at expandable components is their relatively low burst/ collapse rating. But, thanks to the strong patch material, the system actually enhances the rating of the repair or patch site. This means it can be used for both structural repair to casing, and for sealing of leaks or perforations, e.g., as a water shut-off technique. The technique has another important spin-off. Thanks to the materials and expansion method, the effective reduction in wellbore diameter is minimal, limited to the patch wall thickness, typically on the order of 10 mm (0.394 in.). This means access to the well below the patch is almost unrestricted, e.g., a horizontal producer can be perforated at the heel first, then – once production becomes sub-optimal – that section can be patched and the area below it perforated. With certain patch geometries, it is even possible to run one patch through another to set in a deeper interval. BAKER OIL TOOLS Baker Oil Tools has had several additions to its expandable technology offerings since this time last year. Tools referred to here that are not described can be found in the July 2003 issue of World Oil .

EXPatch expandable cased-hole cladding. This system is used to repair damaged or corroded casing or to shut off perforations for water management in cased-hole environments. In short well sections, it can blank off perforations to minimize water inflow. In longer sections, it can repair damaged or corroded casing. In sand control completions, the cladding system can be placed between packers and used with Baker's FORMlock* technology to create a definitive anchor/ sealing section with the host casing. EXPatch* provides a long-term, high-strength solution for casing repair and offers rig time savings and longevity advantages over squeeze cementing. Using the company's catEXX top-down hydraulic expansion system enables one-trip deployment and expansion of an unlimited length of cladding. Using the company's adjustable cone option during expansion results in a metal-to-metal patch with minimal or zero annulus. EXPatch cladding maintains maximum ID after clad placement and can be run in variable lengths to fit various wellbore applications. The cladding's setting mechanism does not rely on the integrity of the surrounding medium to place the clad. The first commercial deployment of the EXPatch cladding system was to correct a casing collapse problem in a vertical workover well in Oklahoma in July 2003, Fig. 5. The cladding system was installed inside a section of 7-in. x 20-lb and 7-in. x 23-lb casing from 3,800 ft to 4,475 ft well depth, in the 20-to-23-lb interface section that had failed when an offset injector well from the original 1950s oil producer went online. The clad was expanded to its full 675-ft length in about 3-1/2 hours and created a definitive casing repair with pressure integrity and minimal well restriction.

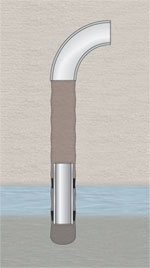

sealEXX* Open-Hole Production Patch. This system is used primarily to shut off water production in openhole environments, Fig. 6, but may also be used to isolate problematic shales, coal seams and other potentially undesirable formations. The sealEXX patch provides long-term isolation and maximum pass-through ID for remedial and logging tools compared to present openhole isolation methods. It is deployed and expanded in one trip. EXXdrill*. This system is an expandable openhole drilling liner that can be used as a temporary solution to selectively isolate lost circulation zones or borehole instabilities encountered during wellbore construction. Designed for use in either management (i.e., planned) or contingency (i.e., unplanned) applications, the EXXdrill system is deployed and expanded in a single trip into an underreamed section of the wellbore. Here it can be used to isolate problem zones and then allow drilling to continue without reducing wellbore size. This ability to allow for continued drilling of the same-size wellbore allows for multiple EXXdrill systems to be deployed in the same well section. The EXXdrill system is similar to the linEXX* Expandable Liner Extension introduced by Baker Oil Tools last year, except that the EXXdrill system is a specific, openhole, standalone, non-cemented wellbore-support mechanism. It is not connected back to the intermediate casing string and does not provide zonal isolation for production purposes. It is a short-term solution for an open-hole drilling problem. WEATHERFORD Expandable products and equipment are designed to reduce well costs and increase productivity, providing value-add alternatives to traditional well construction techniques. Since 1995, Weatherford has been a leader in designing, developing and implementing Expandable Sand Screen (ESS)* and Solid Expandable technologies. Expandable Sand Screens (ESS)*. As of May 31, 2004, Weatherford had expanded more than 36 mi of ESS in more than 280 installations around the world, with more than 60% of them in openhole applications. This represents more than 90% of all global expandable screen installations. In many of these installations, well costs typically have been cut by 20%, and productivity increased by as high as 70%. The system originally was developed as a sand control method that combines the ease of operation that stand-alone screens offer, with the borehole support benefits of openhole gravel packing. The expandable sand screen completely conforms to irregularities in the wellbore and is totally compliant within its design range. This eliminates the annulus, reducing the risks of plugging due to near wellbore particle mixing, and erosion due to hotspots. The large bore that the ESS provides has an intrinsically low flowing friction pressure. In a long horizontal well, this has many benefits: it reduces drawdown, and ensures an even flow along the entire length of the well, which maximizes recovery and delays the onset of water production, Fig. 7.

Solid expandables. Weatherford deployed the Alternative Borehole Liner system – its first openhole expandable liner system – almost 10 years ago. In addition to this slotted expandable product, the company is continuing to build its range for solid expandable technologies. Current offerings include the borehole liner and solid expandable casing repair systems described here. The Alternative Borehole Liner (ABL)*, a slotted expandable tubular technology used in the drilling phase of the well, significantly reduces drilling spending by isolating problem zones with no loss of hole size. Additionally, unlike conventional casing, the system can be run through the previous casing and then expanded across the problem zone without further telescoping of the well. MetalSkin* Solid Expandable Casing Repair System. This is a metal-to-metal expandable casing system designed to solve problems that occur when casing reservoir and fluid production conditions have changed, or when the casing has been worn, corroded or damaged. Technologies under development. Two major expandable systems Weatherford is developing in 2004 are the Slimbore Expandable Openhole Liner and an Expandable Reservoir Completion system. The Slimbore Openhole Liner, a stepping stone to industry's vision of the monobore well, will help reduce well construction costs by minimizing the risks of using solid expandable drilling liners for contingency use and slimming down wells. The initial 7-5/8 -in. x 9-5/8 -in. size will allow operators to extend their 9-5/8 -in. casing string or repair their 9-5/8 -in. casing. The system will be fully commercial in early 2005. Expandable Reservoir Completion system. This sand-control system, which combines solid expandables with ESS in a one-trip system, will provide the zonal isolation functionality of cased and perforated completions with the productivity benefits of expandable sand control. Commercially available early in 2005, it will be a viable alternative to doing a cased and perforated completion or using an Annular Casing Packer (ACP) for zonal isolation. Specific benefits include a simpler, lower-risk and more reliable, mechanical installation and improved longevity due to no loss of inflation pressure or elastomer degradation. Further, it is better suited to harsh well conditions, and improved ID, when compared to an ACP. Beyond these developments, Weatherford will continue R&D work in expandable technology that will help the industry achieve its vision of the full monobore well – commercialization of the Slimbore Openhole Liner is a step in that direction. Another step is developing an expandable FullBore system, a wellbore remediation tool that can have immediate and significant financial impact on well construction. As a contingency solution, the solid expandable casing system allows the operator to install the system, yet drill out with the same size bit as before system installation. Therefore, FullBore can be used to downsize wells, and reduce well construction costs at the well and field level. Longer term, other technologies will continue to be explored, such as a MonoBore Drilling Liner (MDL), which allows the operator to maintain full borehole access, using multiple MDLs in sequence or “nested,” Fig. 8, and the evaluation of high-end technologies for a potential monobore junction. Click here for a complete list of World Oil’s annual expandable technology reports.

|

|||||||||||||||||||||||||||||||

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Drilling advances (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)