Technology from Europe: Technology from Europe:

the Netherlands

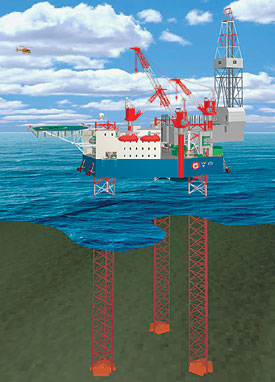

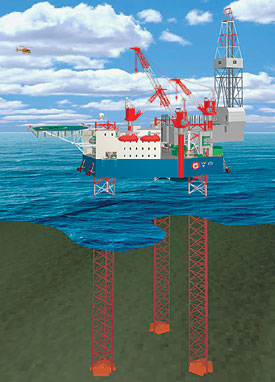

Updated jackup drilling unit for Gulf of Mexico

The MSC CJ series of jackup drilling units are well known in the industry as high-standard units, which can operate worldwide. So far, nine units have been built, eight are operating in the North Sea and Far East areas.

GustoMSC-OceanDesign decided to further develop the CJ46 design to provide a unit optimized for the Gulf of Mexico environment and practices. The CJ series consists of the following units and their operating areas: 1) CJ46: three early '80s units, the North Sea; 2) CJ50: two mid-'80s units, Far East region; 3) CJ62: two mid-'90s units, the North Sea; and 4) CJ70: one unit built and one under construction for the North Sea.

The units are all equipped with rack and pinion jacking and fixation systems. Drilling equipment on the units has evolved from the simple straightforward drilling systems on the CJ46 to the sophisticated, highly automated systems on the CJ70s.

XY cantilever system. GustoMSC has developed a new system, called the XY cantilever. This and its integrated skidding system expand drilling capability/ unit efficiency significantly. The system combines cantilever and substructure/ drillfloor into one fixed package, which can be skidded in longitudinal and transverse direction to reach a larger well pattern.

The major achievement is that combined hook load capacity remains constant over the full envelope of the well pattern. Thus, maximum combined hook load can also be used at the extreme transverse position.

The cantilever and substructure are an integrated system, so no flexible connections are required on the drillfloor/ BOP area. The system is fitted on the two CJ70s built for Maersk Contractors.

CJ46-X100E drilling jackup unit. The objective set by GustoMSC-Ocean-Design was to achieve a unit with the following characteristics:

Superior drilling efficiency: In consultation with primary equipment vendors, an optimal drillfloor layout was created to suit their equipment. An AC drawworks and AC top drive, a mechanized pipe racking system and iron roughneck were selected as a basis for the unit.

Optimal layout of mud pump and generator rooms: Separation of the longitudinal bulkheads in the hull has been increased to fit three 2,200-hp pumps, and five generator sets. If required, the space will accommodate four pumps.

Operations in the Gulf of Mexico in up to 350-ft water, with sufficient preload capacity and a low footing reaction at 8 kips/sq ft: Jacking systems are designed to jack at full preload capacity. Preload pump capacity is designed for 3-hr to 4-hr preloading. Deep drilling capacity requires 15,000 psi and an HP system for wells up to 30,000-ft TD.

HSE aspects are carefully considered. The unit is zero discharge and is equipped with air-cooled radiators. The XY cantilever enables easy handling of cuttings, as containers can be located underneath the cantilever.

After a first round of designs, GustoMSC-OceanDesign touched base with the major US drilling contractors to obtain feedback on design premise and initial design. From these discussions, the CJ46-X100E has been developed to a design package ready for construction.

|

CJ46-X100E jackup for the Gulf of Mexico.

|

|

Jackup description. The design is a three-legged jackup unit with 485-ft legs. Unit layout is concentrated around the XY cantilever, which has a reach of 70 ft clear aft and 20 ft transverse to either side of the rig's longitudinal centerline. The accommodation deck house, sized for 120 persons, is divided into two blocks and connected at main deck level with a covered alley way. This creates a large useful deck space of over 10,000 sq ft.

The XY cantilever is a box-type structure, and the BOP can be handled inside the cantilever in fully upright position from drilling center to storage position. The 2,400/1,500-gpm solids control shaker house is located in the cantilever box. Three marine type diesel-driven pedestal cranes are provided. One deck crane is located on the aft deck to serve the drilling area.

In addition to the selected high-spec equipment, the unit has a large variable load capacity of: 9,000 kips in operating conditions; 6,000 kips in survival condition; and 6,000 kips in transit condition. The unit can jack with full preload capacity.

|

Technology from Europe:

Technology from Europe: