|

| |

|

By Petroleum Technology Transfer Council |

Reverse circulation drilling avoids damage to low-pressure gas reservoirs

Technique allows development of under-pressured formations that would be damaged by conventional drilling, and may not even produce shows when drilled with mud

Paul Mackay, K2 Energy Corp., Calgary, Alta, Canada

PressSol Ltd. of Calgary has adapted reverse-circulation, center-discharge drilling (RCCD) for oil and gas drilling. Because RCCD drilling returns cuttings through the ID of the inner portion of double-wall drill pipe, it does not expose the formation to possible damage from drilling fluid and, thus, is particularly well suited for drilling low-pressure reservoirs.

K2 Energy of Calgary has applied RCCD to successfully drill and test gas wells in the low-pressure (formation pressure estimated at 150 psi) Bow Island formation on the Blackfeet Indian Reservation in northern Montana, US. As of February 1, 2003, the system has been used to drill 11 Bow Island wells on the reservation and an additional five wells in the Thrust Belt. Drilling cost is competitive with mud or air drilling in that area; $15/ft for surface string to 600 ft and $10/ft for a long string to 2,500 ft. The system can be adapted to any rig with the addition of a dual-wall drillstring.

RCCD DRILLING

K2 Energy has demonstrated a successful application of RCCD drilling technology in two tests of the under-pressured Bow Island formation in northern Montana. RCCD drilling technology was developed to drill fractured, under-pressured reservoirs that can be damaged by conventional drilling methods using mud, foam or high-pressure air. The technology was tested during the spring of 2002 by twinning two conventionally drilled wells that detected no shows or porosity in the Bow Island. The RCCD-drilled wells flowed gas from the Bow Island without stimulation.

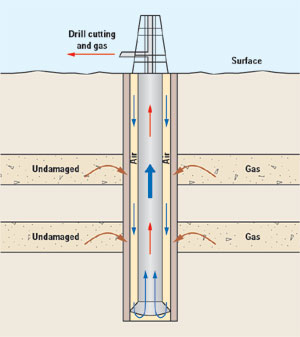

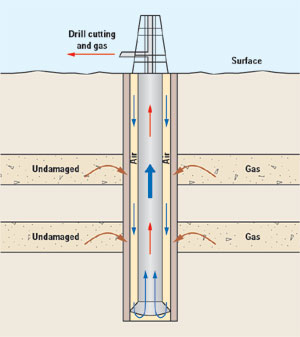

The PressSol Ltd. RCCD system is based on hard rock exploration reverse circulation drilling that was developed to provide an accurate and less expensive alternative to coring. Reverse circulation drilling uses a dual-wall drillstring. Drilling fluid is carried to the bit between the outer and inner wall of the drill pipe and cuttings and fluid are returned to the surface in the inner pipe, Fig. 1. When used in hard rock drilling, RCCD provides an uncontaminated cuttings sample equivalent to core, because cuttings and drill fluid travel to the surface in the drill pipe and are not exposed to loss and contamination that would occur if they traveled up the pipe-formation annulus.

|

FIG. 1. Reverse circulation drilling uses a dual-wall drillstring. Drilling fluid is carried to the bit between the outer and inner wall of the drill pipe, and cuttings and fluid are returned to the surface in the inner pipe.

|

|

Because the formation-drill pipe annulus is not used as a conduit to return drilling fluids – which subjects easily damaged formations to invasion and damage from mud hydrostatic pressure, pump pulses or high pressure air and cuttings – PressSol Ltd. reasoned that reverse circulation drilling would be an ideal system for drilling easily damaged, low-pressure formations. However, because reverse circulation drilling was originally developed for hard rock drilling, it could not be used to drill for oil and gas because it did not have the necessary safety equipment.

The safety limitations of reverse circulation drilling have been overcome by developing a patent-applied-for RCCD system. The system consists of a downhole blowout preventer/shutoff valve, a surface blowout preventer, a surface kill valve-diverter and blewie line that make RCCD safe. The patent-applied-for downhole blowout preventer/shutoff valve prevents gas from escaping to the rig floor during tripping or joint changes. The rotating head blowout preventer seals the annulus and drillstring at the surface; the kill valve-diverter is attached to a 100-ft blewie line that carries cuttings to the pit. When drilling in a gas target zone, a propane torch is kept at the blewie line discharge to flare-produced gas. With the addition of dual-wall drill pipe, the RCCD system can be used on any drill rig.

FIELD RESULTS

K2 Energy tested the RCCD system by re-drilling two conventionally drilled wells that had penetrated the Bow Island. K2 theorized that gas was present in the Bow Island in the area, but was not detected in the mud-drilled holes because of formation damage caused by drilling mud.

The Bow Island formation was deposited during Cretaceous time and is made up of marine shale with interbeded sandstones. It is productive in Alberta and northern Montana from fields such as Big Rock with 17 Bcf of cumulative production and Blood field with 49 Bcf. The formation is under-pressured in this area. Blood field is typical of Bow Island production. At a depth of 3,300 ft, it has a pressure of 200 psi, while hydrostatic pressure for that depth is 1,400 psi (3,300 ft x 0.433 psi/ft).

The rig for the test was provided by Midnight Sun Drilling, Dawson, Yukon Territory, Fig. 2. The outside diameter of the dual-wall pipe was 412 in. and ID was 2 78 in. A downhole air hammer was used to reduce dust emissions. Drilling fluid was air. The holes did not make any water.

|

FIG. 2. Midnight Sun Drilling provided the rig for the RCCD field tests. The dual-wall drill pipe was 412-in. OD by 2 78-in. ID. A downhole air hammer was used to drill. Drilling fluid was air.

|

|

The first well twinned was Tesoro 3-14 on the Blackfeet Indian Reservation. The well was originally drilled with mud in 1975 to test the Cutbank formation at a depth of 3,300 ft. The Cutbank was cored; no shows were detected in core and the well was abandoned. Top of the Bow Island was reported in the mud log, but no porosity zones or gas shows were reported. In the spring of 2002, K2 Energy twinned the well as Palmer Bow Island 3-14, re-drilling it using the RCCD drilling system. The well was drilled with air to a TD of 2,400 ft. It was not cased below surface sting.

During drilling, the RCCD system showed several benefits over conventional drilling. Sample lag time is short; cuttings are not contaminated by contact with overlying formations; and most importantly, because the formation is not subject to hydrostatic pressure of returning drill fluid (mud or air), any formation gas will migrate into the wellbore and is quickly evident as a flare at the blewie line.

Tucker Wireline Services, Leduc Alberta, logged the well in air. A conventional four-point test and Darcy evaluation indicated that the Bow Island was non productive. In spite of this, the well was tested. Because the Bow Island is a low-pressure reservoir, it is produced with suction. Accordingly, the Palmer Bow Island 3-14 well was tested by simulating production: three days under a suction of 2 in. of mercury and flowed 155 Mcfd.

The second well twinned was Sherburne Estate #1. The well was drilled in 1965 to a TD of 3,351 ft to test the Cutbank formation. The Bow Island was not noted in the mud log and no shows or porosity was logged in the Bow Island interval. K2 Energy twinned the well as Palmer 10-2. The well was cased to the top of the Bow Island at 1,800 ft; the lower 600 ft were left open. As in the Palmer Bow Island 3-14, the well was tested with a suction of 2 in. of mercury and flowed 97 Mcfd during a 5-day test.

These two tests show that the RCCD system can be used to drill and produce tight low- or under-pressured formations that otherwise would be damaged by conventional drilling, and may not even produce shows when drilled with mud. It can be applied to a wide range of low-porosity/permeability formations including shale and coalbed methane.

THE AUTHOR

|

| |

Dr. Paul A. MacKay is president and CEO of K2 Energy Corp. His 22-year career includes positions as a geologist, geophysicist and manager with companies including Amoco Canada, Morrison Petroleum and Northstar Energy, as well as consulting projects with other companies. Before assuming the position of president and CEO in December of 2002, Dr. MacKay was engaged as a consultant to K2 Energy. He holds BS, PhD degrees in geology. mackay@k2energy.com

|

| |

|

|