New foam fracturing technology unlocks lower porosity reserves

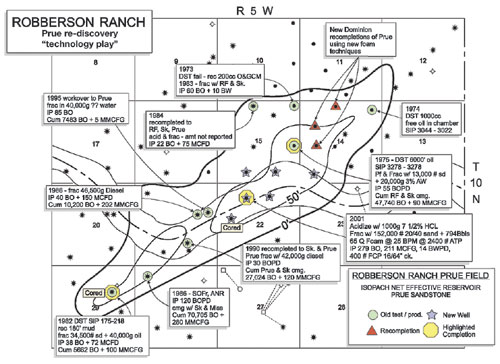

New foam fracturing technology unlocks lower porosity reservesDominion Exploration and Production Company, Oklahoma City, OK; and Les Broker, * Broker & Capucille, Edmond, OK Bottom line. Using newer foam fracturing technologies, Dominion E&P has unlocked reserves – an estimated 1.5 million bbl of oil from six new wells and three re-completions – in the lower porosity (10%-to-12% range) Prue sandstone. The site is in Roberson Ranch field, southwest of Oklahoma City. Fracturing of earlier, 1970- and 1980-vintage wells – using what were then state-of-the-art, liquid-based fluids – had not been effective there. However, toward northeast of the field, where porosities were higher, in the 16%-to-18% range, the fluids had worked to some degree. Problem addressed. Early Prue sandstone wells in Robberson Ranch field, although looking good on logs and in drillstem tests (DSTs), never produced to their potential when completed, and were uneconomic. In hindsight, poor results were due to fluid blockage effects with lower porosity sands. Historical Prue development. The Lower Pennsylvanian Prue sandstone was originally recognized as productive in the area in 1932, when giant Oklahoma City field was being developed. The openhole completions used then probably produced oil from the Prue, commingled with Simpson sands. In 1965, Cities Service initiated a Prue waterflood in the southern end of Oklahoma City field. No further development of the Prue sandstone took place until 1981, when a "Sooner Trend" extension well at Will Rogers World Airport, 10 mi west of Oklahoma City field, encountered 60 ft of productive Prue sand with 14%-to-16% porosity. Development eventually tied a Prue, incised valley fill sandstone eastward into the old Oklahoma City field. Three waterflood units currently produce Prue reserves, with cumulative output totaling 8 million bbl of oil and 47 Bcfg. Secondary recovery, to date, is 3 million bbl of crude, with ultimate flood oil reserves expected to equal primary production. Most of the wells in these three units were initially treated with diesel or oil fracs, which were state-of-the-art for the early 1980s. Results were good, with initial potentials occasionally reaching more than 1,000 bopd. Primary cumulative production volumes exceeded 100,000 bbl/well. Disappointing results in early field wells. In the 1970s, the companies developing Robberson Ranch field in the southern end of Mustang field, and south of the Prue production discussed above, recognized that the Prue sandstone was hydrocarbon-bearing. DSTs in three 1970s-vintage wells recovered free oil from the Prue. One of these Prue DSTs, in the Jones and Pellow Robberson Ranch 15-2, recovered 6,000 ft of free oil with shut-in pressure of 3,254 psi from 75 ft of Prue sand (see well location map). When the targeted Hunton formation proved unproductive, a Prue completion was made. The Prue sandstone was fractured with 13,000 lb of sand and 476 bbl of 3% acid water, which was considered a typical frac for that time period. It was also completed in the Skinner and Redfork formations – initial potential from the three commingled zones was only 55 bopd. Cumulative production from the three zones is about 48,000 bbl of oil and 90 MMcfg. By the early 1980s, the Prue sandstone had been recognized as a basin-ward continuation of the incised valley system that was productive to the northeast under Will Rogers World Airport. Czar Resources drilled a Prue well in S29-T10N-R5W, encountering 70 ft of clean Prue sandstone with 9%-to-12% porosity (well location map). A completion was made, and the Prue was diesel-fractured. Initial potential was only 38 bopd, and production soon declined to the 5-bopd range. Cumulative production some 16 years later was less than 6,000 bbl, with 100 MMcfg. From 1982 to 2000, several additional wells were completed in the Prue sandstone, but results using water or diesel gel fracs continued to be disappointing.

Results with binary foam technologies. In the 1990s, foam fracturing with much larger sand volumes became the standard for lower Pennsylvanian sands in Grady County, Oklahoma. Initial potentials and ultimate reserves were significantly higher than for earlier gel jobs. In 2000, Dominion E&P recompleted a depleted producer in the southern end of Mustang field at Robberson Ranch into three zones. The Redfork, Skinner and Prue sands were individually fractured with foam / sand jobs during one continuous operation and immediately commingled for production. Output one year later indicated greatly improved productivity, relative to earlier wells. Dominion commenced a development drilling program that targeted the Prue sandstone. Dominion’s Turnpike Federal 1-22 encountered 76 ft of Prue sand (well location map). This zone was hydraulically fractured with 152,000 lb of 20/40 sand and 794 bbl of 65-quality foam at 25 bpm down 4-1/2-in casing. The well flowed up the casing for 16 days, averaging 279 bopd and 211 Mcfgd before production was commingled with the Mississippian. Six successful Prue development wells have now been completed, and drilling continues. Additionally, several old Hunton wells have been recompleted to the Prue, using newer stimulation approaches. Initial estimates of field reserves are more than 1.5 million bbl. Porosity in Robberson Ranch field is in the 10%-to-12% range, as compared to 16% to 18% in the Oklahoma City area. This lower porosity makes the Prue sandstone sensitive to water blockages with fluid-based frac jobs. Newer hydraulic fracturing technologies, using binary foam, minimize potential blockage and, when larger sand volumes are used, completions can exhibit higher productivity. Lesson learned. Significant technology advancements have occurred in most areas of the oil patch during recent years. To realize the full potential of these advancements, one must often "look beyond" earlier poor results, asking two key questions: 1) Why might earlier results have been poor with then-current technology?; and 2) What should results be with today’s technology? Dominion did this with what appeared to be a productive Prue sandstone reservoir in Robberson Ranch field. There was a logical explanation for earlier poor results, and the drillbit and completion rig have confirmed good success with today’s technology. There are many similar opportunities lurking throughout the patch. PTD Acknowledgment This information was presented during the Oklahoma Geological Survey’s workshop, "Finding and Producing Cherokee Reservoirs in the Southern Midcontinent," May 14 – 15, 2002, in Oklahoma City. A special acknowledgment goes to Sam Roark, a geologist with Dominion Exploration and Production Co., and to Dominion E&P corporately for permission to publish this case study.

|

|||||||||||||||||||||

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- What's new in production (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)