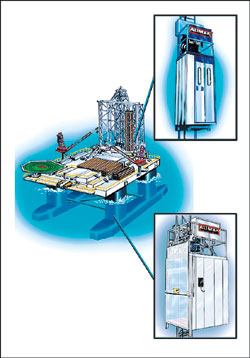

Alimak AB, based in Skellefteå, Sweden, has received an order for a 450-kg (1,000-lb) capacity personnel lift to be installed in the derrick of the Kvitebjørn fixed-steel production platform. The rack-and-pinion driven lift will have its electrical equipment explosion-protected for Zone 2 operation. The Kvitebjørn lift will be provided with a new type of lift-control system (ALC), a car-operating system recently developed by the company for use on its permanent industrial lifts, as well as on passenger / materials construction hoists. Lifts provided with the ALC control system can be operated from a keypad in the car, serving a total of 32 floors (or landing levels), or from a push-button station in the car, handling 4 – 16 floors. The lift controller system allows an alternate control choice: a simple, semi-automatic set-up, with only Up, Down and Stop-Next-Landing buttons, if that is more suitable for a specific installation. Total travelling height of the lift is 29 m. Other recent contracts for offshore lifts awarded to the company include two lifts being produced for a new semi-submersible for Global Santa Fe, currently under construction at the Jurong Shipyard in Singapore. These lifts will be installed in two of the hull columns of the semi-sub. The required payload capacity of the lifts is 1,000 kg (2,200 lb), and total travel length is about 30 m.

Two access lifts with 1,200-kg (2,650-lb) lifting capacity will be installed on the Valhall steel-jacket drilling rig in the North Sea. The lifts will be fitted to the outside of the rig and travel a distance of 11 m and 18 m, respectively. Built by Keppel FELS in Singapore, a new Maersk semi-submersible will operate in the Caspian Sea starting in 2003. Alimak will supply two access lifts in the hull columns, with a lifting height of 30 m and a transport capacity of 500 kg (1,100 lb). General lift design. These lifts are based on a modular design, enabling specific customer requirements to be met by using proven standard components. The system provides an infinitely variable range of lifting heights, car sizes and capacities capable of meeting the most stringent specifications. The lift car and drive systems are completely wired and factory tested before delivery, which ensures fast installation at the job site. The rack-and-pinion drive technology has proven superior to other types of drive systems in demanding industrial environments. The following major benefits can be identified:

The company has been supplying its rack-and-pinion operated lifts to the offshore industry since 1974, with about 500 lifts delivered into this specialized market. They replace potentially hazardous stairways and ladderways. |

|||||||||||||

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Offshore technology: Platform design: Is the next generation of offshore platforms changing offshore energy? (December 2023)

- 2024: A policy crossroads for American offshore energy (December 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)