Cybernetix Group, Marseilles, France Offshore Angola, in Block 17, TotalFinaElf E&P operates Girassol oil field, a major, ongoing development project. Field partners include state firm Sonangol, as well as ExxonMobil, BP, Statoil and Norsk Hydro. On behalf of TotalFinaElf, the AMG (Alto Mar Girassol) consortium (Stolt Offshore and Bouygues Offshore) awarded a contract to Cybernetix for instrumentation and monitoring of the dynamic behavior and temperatures of the riser towers and export lines at Girassol.

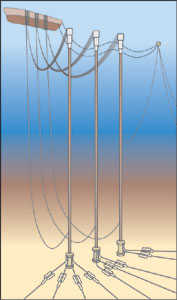

In deep water, the flowline and riser systems are a live, dynamic integrated part of the production system. They are designed with a fatigue safety factor of at least 10. While many flexible risers and a few steel catenary risers have been used for the past 10 years, the riser towers and suspended export lines to be installed this year at Girassol field will be the first of their kind. To control the riser towers’ VIV (vortex-induced vibration) and structural load at the critical taper joints, the consortium designed an overall system using strain gauges and motion reference units. The system is to be installed by ROV onto the riser towers and the 16-in., suspended export lines. Data will be recorded every day, to take into account cyclic events. The underwater recorders will be recovered every six months by ROV during a period of one to two years and analyzed for TotalFinaElf by a group consisting of Cybernetix, Metravib and GAIA. The motion reference units will provide information regarding natural vibration frequency and amplitude to crosscheck fatigue analysis of the riser towers. Load cells on the taper joints will provide strain & stress values that will be crosschecked with the natural frequency values from the motion recording unit. The load cells on the 16-in. export line will confirm the line’s actual tension and bending moment, due to CALM buoy motion and flex-joint stiffness. Natural export line frequency will be defined and compared versus periods and CALM buoy RAOs. Monitoring and data collection could be considered very useful for reducing design safety factors. According to international standards, the design of underwater systems shall take a safety coefficient of 10 for fatigue life calculation, if such structure cannot be inspected and monitored. Obtaining reliable information to enhance the design of underwater structures is certainly one of the key issues in reducing costs and defining the technology required to develop deeper subsea fields in a safe environment. Similar monitoring systems could be used on drilling risers to allow larger displacement of the drilling rig required – for instance, during parallel pipeline installation activities and drilling completions. This could be achieved by controlling load and bending transfer at the BOP and riser. The contract also includes local temperature monitoring at the riser base on the outer skin of the pipe and underneath the insulation coating. The data collected will be recovered every three to six months, or they could be gathered directly by the ROV. The system is also designed for online temperature monitoring by acoustic modem. |

|||||||||||||

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Offshore technology: Platform design: Is the next generation of offshore platforms changing offshore energy? (December 2023)

- 2024: A policy crossroads for American offshore energy (December 2023)