France: JIP proposes to study plugging materials for well abandonments

Apr. 2002 Vol. 223 No. 4 European Technology Round Up

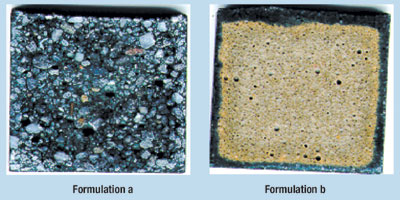

Institut Français du Pétrole, Paris Sooner or later, all wells at certain periods in their lives will be abandoned and require plugging. Inactive, improperly abandoned wells can become a significant threat to the environment by polluting groundwater quality and/or marine ecosystems. Oil companies’ onshore field experiences show that wells abandoned a few years ago sometimes exhibit leakage due to a lack of plugging set-up in wells. While it may be no problem to perform a remedial job in an onshore field (only expenditures could be critical), doing an offshore remedial job could have a dramatic cost effect. Consequently, abandonment of offshore wells must be considered carefully. Each abandonment’s objective is to protect the remaining reserves and the environment (in particular, water reserves), and to limit fluid movement within the wellbore until nature restores the pressure balance that existed before the well was drilled. Concerning the barrier materials, requirements include low permeability, long-term integrity, no shrinkage and ductility. IFP proposes that a JIP be formed with two goals. First, criteria would be defined for formulating new plugging materials with appropriate mechanical properties. Second, the long-term reliability of materials used to plug wells would be demonstrated. Prime objective of plug-and-abandon operations is to provide zonal isolation for an "infinite" time. However, after production ceases and a well is abandoned, various processes resulting from variable downhole conditions lead to stress changes within the cement sheath and plugs. Stress variations are the cause of damage to cemented zones. The failure of cement plugs can be either micro-annulus formation or cement cracking, depending on variations in downhole condition. Thus, the design of new plugging materials has to take into account the appropriate cement mechanical properties needed to avoid these conditions. The answer to this crucial question for long-term, cement mechanical integrity is this: mechanical loading applied to the well has to be calculated. The objectives of the JIP’s first phase are to calculate the loading on the wells and then to define optimum cement mechanical properties. By coupling a reservoir simulator and a geomechanical model, one can compute the mechanical load applied to the well. This load can then be used in finite element software to analyze the plugging material’s behavior. This last step will give target values for mechanical parameters (Young’s modulus, compressive and tensile strengths, etc.), to avoid damage to cement plugs. If cement durability is a key parameter to ensure oil production during a field’s exploitation, then long-term properties of cementitious materials become very important for permanent well abandonment. Until now, little attention has been paid to cement durability in oil wells, and to understanding the physical and chemical processes causing cement degradation (see photos).

During the second phase of the JIP, plugging materials will be cured and stored at controlled pressure and temperature in aging cells. After setting, plugging material cores will be aged in contact with an aggressive chemical mixture (hydrocarbons, H2S, etc.). At fixed periods (six, 12 and 18 months, for example), plugging material performances will be measured and their structures characterized. The final objective is to understand mechanisms related to the aging of plugging materials, to accurately predict the lifespan of plugs in permanently abandoned wells. |

|||||||||||||

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Drilling advances (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)