Designing a water shut-off treatment for fractured, multi-layered sandstone

Designing a water shut-off treatment for fractured, multi-layered sandstoneLeo A. Giangiacomo,* P.E., Extreme Petroleum

Technology, Inc., Casper, Wyoming Bottom line. Thorough research and design increased the probability that a gel-polymer water shut-off treatment of a Tensleep producer at Teapot Dome would be successful. The treatment did not go as planned, even with real-time modifications to the treating procedure, based on Hall plot data. It did significantly reduce water production and operating expenses, but oil production was not increased. Additional treatments and thorough post-treatment analysis will help develop a set of experience-based guidelines tailored more specifically to this reservoir. The problem: Water channeling. The Tensleep reservoir at Teapot Dome is a naturally fractured, multi-layered sandstone with interbedded 3olomites. Net thickness varies from 10 to 100 ft. Porosity can range to 20%. The matrix rock has oil saturations up to 61% and is thought to be oil-wet. Water channels through the natural fracture system from the underlying Madison aquifer, limiting matrix oil production. Tensleep producers are pumped with high-volume electrical submersible pumps (ESPs), and have very low oil cuts, ranging from 0.05% to 0.8%. All wells exhibit similar performance, confirming that water production is a reservoir-wide phenomenon, not an individual well problem. Production tests have shown that oil cut improves at higher withdrawal rates. At a very high draw-down pressure, withdrawal rates reach a limit and oil cut increases exponentially, demonstrating that water production is limited by fracture conductivity. Treatment design. Cross-linked polymer gels are an appropriate solution for plugging the fracture system. The strategy is to place a rigid, high-molecular-weight, cross-linked polymer gel into the fracture system, excluding it from infiltrating the rock matrix. The gel must withstand high pressure differentials when the well is pumped off, and remain in place over the life of the producing well. To control polymer infiltration into the rock matrix, a very high-molecular-weight polymer was selected, and crosslinking was designed to occur near the perforations. Treatment volume should be related to the fracture system volume. Under-sized treatments may fail due to water reestablishing a flow path around the treatment, while over-sized treatments may place gel into offset wells or risk economic failure due to high costs. Lacking direct experience in the Tensleep at Teapot Dome, the treatment was sized by analogy to treatments in the Big Horn basin. There, volumes range from 12 to 76 bbl per ft of perforated interval. For this initial treatment, 25 bbl per ft of perforated interval was used. By similar analogy, polymer concentration was designed at 5,000 ppm during the first 90% of the treatment volume, then increased to 8,000 ppm for the final 10% volume. Experience in the Big Horn basin had indicated that higher concentrations, while more effective at shut-off, could shut off oil production, too. Experience in the Big Horn basin indicates that combining gel technology with extreme-over-balanced perforating or propellant stimulation improves communication with the fracture system near the wellbore and minimizes treating pressure. Propellant stimulation was selected based on cost. Detonation speed or order of propellants determines the nature of the stimulation. When speed is too slow, a classic hydraulic fracture can occur. When speed is too fast, rubble can be created, as in the case of nitroglycerine. An optimized detonation order causes a sphere of cracks around the perforations without damaging wellbore equipment. Computer simulation using rock mechanics and wellbore geometry was used to design the propellant stimulation. Screening candidate wells. To minimize expenditures on equipment and facilitate post-project evaluation, only active wells with good baseline production were considered. The wells were ranked according to:

Based on log analyses, oil-in-place per acre was estimated for each well. Open flow potential was estimated from existing production rates and fluid levels, and current percent of open flow potential calculated. Screening economics were performed using a $60,000 job cost, projected oil production at a pumped-off condition and half of the current water production. Wells with the highest rank in the combined categories were selected as treatment candidates. Well 76TpX10, one of the most favorable candidates using these criteria, was selected for the water shut-off treatment. Planned treating procedure. The planned procedure was:

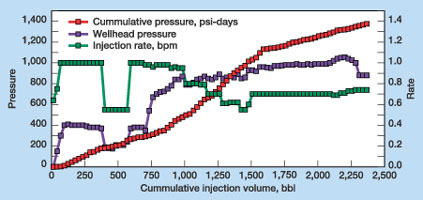

The above treatment is then over-displaced with 73 bbl of water and shut in 72 hr. Offset Tensleep producers are shut-in during the treatment. A real-time Hall plot is made to provide data for making adjustments during the treatment. Estimated cost for this treatment design was $59,000. Gel services and stimulation represented 37% and 25%, respectively, of that cost. Treatment-specific economics, with oil declining 25% annually from 20.5 bopd (risked at 90% chance of success) to the economic limit (using $0.03/bw cost for water production), yielded a net present value (10% discount rate) of $80M. Payout will occur within eight months. Performing the treatment. Water transfer pump problems extended the preflush to 981 bbl. Pressures quickly increased once polymer injection began. Polymer concentration and pump rate were steadily dropped to 4,500 ppm and 0.5 bpm, to delay premature termination due to excessive injection pressure. Despite this action, the Hall plot maintained a concave upward curve, Fig. 1.

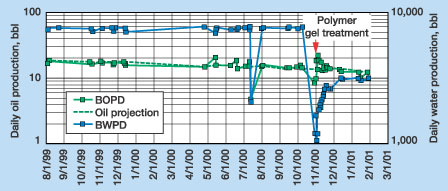

After pumping 1,000 bbl of gel, concentrations were increased from 5,000 to 8,000, and finally to 10,000 ppm, to place a stiffer slug near the wellbore. The Hall Plot slope unexpectedly changed from concave upward to a lower-sloped straight line. After 1,377 bbl of polymer, a small over-displacement was pumped and the well was shut in for four days. Production results. Based on swab results, the prior ESP design was too large. A smaller ESP had to be designed and installed, bringing job cost up to $81,000. After an initial surge to 22 bopd, oil production returned to pretreatment decline, Fig. 2.

Water production increased from 1,200 bpd to 3,150 bpd during the first 4 to 6 weeks of production, still only 40% of pre-treatment rates. After three months, the treatment economics are marginal, although operating costs have been reduced significantly. With the short post-treatment history, results are still inconclusive. Lessons learned. Treatment design must consider both theory and experience in analogous reservoirs. Even with thorough research and planning, experience in the particular application is critical to success. Real-time monitoring of the treatment with Hall plots is necessary to make mid-job adjustments. The concave upward shape of the Hall plot during the early part of the treatment usually is interpreted as accumulating damage. However, in a gel treatment, it may be due to crosslinking or dehydration. The break-over to a straight-line behavior at the later part of the treatment may indicate the damage mechanism was overcome, or that the treatment was breaking into the main water-filled fractures. The treatment significantly reduced water production and operating expenses, but did not increase oil production. Additional treatments will help answer these questions and improve success. A treatment program consisting of a series of well-planned and thoroughly analyzed individual well treatments is necessary to minimize the learning curve. PTD Acknowledgment This case study was originally presented in a workshop developed by the Rocky Mountain Oilfield Testing Center and co-sponsored by PTTC on Oct. 13, 2000, in Casper, Wyo. Treatment results are detailed in SPE Paper 71080, "Design and Execution of a State-of-the-Art Water Shutoff Treatment in a Powder River Basin Tensleep Producer," which is being presented at the SPE Rocky Mountain Petroleum Technology Conference in Keystone, Colo., May 21 – 23, 2001.

|

||||||||||||||||||

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)