Inhibitive mud drills sensitive clays

April 2000 Vol. 221 No. 4 Feature Article Inhibitive mud drills sensitive clays Two water-based mud systems were used for drilling large diameter sections of Well SP 1

Inhibitive mud drills sensitive claysTwo water-based mud systems were used for drilling large diameter sections of Well SP 1 in the Central Apennine region of Italy. The well was drilled using a program based upon geological data provided by offset wells PPN 1 and PPN 2. While drilling the 28-in. section, it was anticipated that a 650- to 985-ft thick limestone formation (Ateleta) would be traversed. Later, the 23-in. section would penetrate the Argille Varicolori shale formation (165 to 330 ft thick) and the Tortonian Flysh (4,265 ft thick). Problems expected when drilling these sections included:

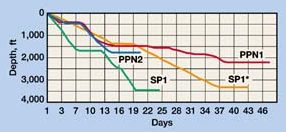

As discussed below, use of a proper mud program allowed these difficulties to be overcome and these sections were completed while saving substantial time and money. Objectives. The operator’s objectives were to drill the sections as cost-effectively as possible by reducing drilling time and reducing circulation losses in the carbonate formations. If successful, the company estimated savings of about $55,000. More importantly, the specific hydrogeological situation presented by the Ateleta limestone required special efforts to minimize impact on the environment. The Ateleta aquifer feeds many springs downstream, as confirmed by a water flow observed while drilling the 42-in. conductor hole. In addition, the economic damage would be severe if an adverse environmental impact occurred (negative advertising, sanctions for infringing on environmental laws, investment restoration and difficulty in obtaining new permits). Actions. To drill the referenced sections, AVA S.p.A. of Rome, Italy, recommended the following mud program. For the 28-in. section, a fresh water, gel polymer FW-GE-PO, biodegradable mud system was designed with an SG of 1.14. Primary components were regular bentonite, xanthan gum biopolymer Visco XC 84 as viscosifer and polyanionic cellulose Policell SL as filtrate reducer. Rig operating conditions allowed the SG to be maintained between 1.03 and 1.07, minimizing losses in the hole as much as possible. Lost circulation was controlled by pumping LCM pills comprising fine, coarse and granular mica. Mud properties were maintained as programmed, and no problems were encountered. At the end of the section, the mud was reconditioned and recovered for the following 23-in. section. For the 23-in. section, AVA recommended the Avaclayblock system, which is specifically designed to minimize hole instability problems that mostly occur when drilling shale. The key components of this system are a mixture of polymers, potassium salts and silicate, dispersed in an aqueous solution and characterized by a marked inhibiting action that prevents clay hydration, consequent dispersion in the mud and hole instability problems. The product does not affect mud rheology and can be used at temperatures higher than 150°C. The system also utilized the polyol Avabiolube, which is a totally water-dispersible, natural polymer. It acts as lubricating agent, as well as an inhibiting agent, on clay platelets, modifying the mechanism of their hydration by "cloud point" behavior. (Cloud point is the temperature forcing the polyol to separate from the water phase.) The product is totally natural and environmentally friendly. No specific hole problems were encountered during drilling, except for the last 262 ft of the section, where chunks of shale were breaking off the formation as a result of an insufficient clay inhibition. The problem was solved by increasing Avaclayblock and Avabiolube concentrations. Results. The accompanying chart summarizes penetration rate data for Well SP1. It also includes data from Wells PPN1 and PPN2, in which no clay inhibitor was used. The 28-in. section was drilled from surface to a depth of 1,689 ft in seven days. The subsequent section was drilled to a depth of 3,442 ft (1,762 ft drilled) in 13 days.

Penetration rates in SP1 were higher than expected, compared to Wells PPN1 and

PPN2, in which a series of technical problems (partially related to the mud system) were encountered. The

effectiveness of the mud used in the 23-in. section of SP1 was supported by results of a caliper survey that

showed the drilled section to be nearly the same diameter as the cased hole. Better geological knowledge and

improved technology also accounted for the better performance. The higher penetration rate produced a 10-day

drilling time reduction, compared to projections. Additionally, about $600,000 was cut from drilling costs.

|