Vertical and horizontal redrills tap bypassed reserves

Vertical and horizontal redrills tap bypassed reservesSteven F. Coombs (coombs@pacops.com), Edwin Edward, and William Fleckenstein, Pacific Offshore Operators, Inc., Santa Barbara, Calif. Bottom line. Production was increased by 850 bopd in a section of the offshore California Carpinteria field held by Pacific Offshore Operators Inc. Zones that had not been adequately drained by existing wellbores were accessed through a vertical-horizontal redrill program. Field history. Carpinteria field is located seven miles offshore California in the Santa Barbara Channel. Discovered in 1964, the field was developed from two platforms on state leases (Hope and Heidi, set in 1965) and three platforms on federal leases (Hogan and Houchin, set in 1968; and Henry, set in 1980), Fig. 1. Pacific Offshore Operators, Inc. (POOI) acquired the federal lease containing Hogan and Houchin in 1990, followed by the state lease in 1996, after Heidi and Hope were abandoned.

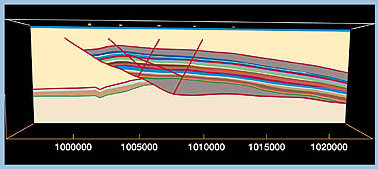

Productive intervals in the Carpinteria field are deepwater turbidite-type sediments from the early Pliocene age. Bundles of individual turbidites form productive sandstone zones from 20 to 180 ft thick. As many as 29 producing zones have been identified, Fig. 2. The productive sandstones are interbedded with siltstones and claystones at subsea depths between 2,500 and 5,500 ft.

Structurally, the field is part of the Rincon anticlinal trend. At Carpinteria, the anticline slopes gently to the east and is intersected by a south-dipping thrust fault. Known as the Hobson Fault, it acts as the dominant trapping mechanism by changing direction to cross the structural axis in an up-dip position, preventing further migration of hydrocarbons to the west. There are productive intervals both above and below the fault, which are referred to as the suprathrust and the subthrust, respectively. The field’s 50 wells produce a total of 2,700 bopd. Half of them are POOI’s wells (Lease OCS P-0166), which average 1,650 bopd, along with 4,500 bpd of water and 1.1 MMcfd of natural gas. High water production decreasing oil recovery. The commingling of oil- and water-bearing zones in wellbores, along with the lateral influx of water, has caused high water production rates in the field. As a result, many wells have been shut-in, leaving behind significant quantities of oil in zones that were not adequately drained. Only 19% of the estimated 521 million bbl of the original oil-in-place (OOIP) has been recovered (98 million bbl). Identifying recovery options. Undepleted zones in the field’s existing wells were a challenge to identify, since most well logs were from the 1960s. It also was difficult to run production logs in rod-pumped wells, and expensive to pull either the rod-lift wells or the gas-lift wells. Increased understanding of the geologic framework, through reservoir characterization, modeling and using existing data, was essential to optimizing field redevelopment. POOI obtained U.S. DOE funding for two cost-shared projects that supported the planning and implementation of Carpinteria’s redevelopment. The first was the advanced reservoir management (ARM) Project, a cooperative effort begun in 1994 among POOI, Los Alamos National Laboratory, the U.S. Minerals Management Service and the California State Lands Commission. The project used 3-D modeling and simulation to better identify target intervals for redevelopment. The ARM project directly supported the second undertaking, a Class III field demonstration to help fund the initial redevelopment of six redrilled wells. Reservoir characterization included significant geologic work to thoroughly map and correlate the productive zones, and to identify target intervals for redevelopment. The analysis of Carpinteria field led to an extensive redevelopment plan that included: 18 to 27 horizontal redrills, five to nine vertical redrills, 20 to 30 workovers, six to 15 long-reach wells to the state leases, a pilot waterflood and, possibly, the installation of a full-field waterflood. Creative computer solutions. One of the field study’s challenges was to develop a 3-D geological model using a state-of-the-art software package. POOI selected Dynamic Graphics, Inc.’s Earthvision software, and teamed with another company with a Class III project, Strata Production Co., to share the software license by floating a license token over the Internet. This innovative solution — involving Strata, POOI and Dynamic Graphics — enabled POOI to use an otherwise unaffordable software package when modeling Carpinteria field. Workover program. By 1997, reservoir modeling efforts had identified some definitive target zones that, if adequately developed, would improve oil recovery. Several workovers isolated various zones, confirming the geologic and engineering models and helping to identify potential targets for sidetrack and redrill operations. Based on these results, a rig was mobilized at Hogan in 1998. Two vertical redrills were done first to get log data using modern logs and determine current saturation values. These wells then were selectively perforated in the saturated intervals. Using this information, POOI did four horizontal redrills to exploit specific intervals. Redrilling operations. In addition to confirming oil saturations, early field work tested the feasibility of redrilling from 7-in. casing and producing through a 5-1/2-in. liner — an approach that enables use of a smaller rig. A combination workover / drilling rig with a 240,000-lb mast was chosen to minimize costs. Cost control and program flexibility were critical. The typical redrill program was comprised of:

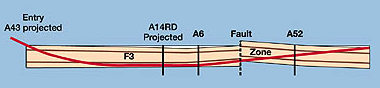

The well profiles were designed to enter the zone at 60°, complete the 10° to 12°/100 ft build to horizontal and then build to 5° to 10° past horizontal, effectively producing a U-shaped well path. This allowed the horizontal section to penetrate each of the discrete sand lobes, and cross any thin shale stringers within the lobes, Fig. 3. Maintaining a low-solids, clay-based mud through zones of lost circulation and using a polymer-based system through the completion interval were critical to drilling the boreholes with the smaller rig.

Measurement while drilling (MWD) and geosteering techniques guided horizontal drilling. The horizontal wells were programmed to make a sweeping trajectory through the intervals of interest with 500- to 1,000-ft lateral sections. The wells’ success hinged on geosteering, which used real-time gamma ray and resistivity log data. The six wells that were drilled in 1998 now produce about 850 bopd, with only 285 bwpd. For the redrill program, the discounted return–on-investment (using a 10% discount factor to reflect the time value of money) was 2.5. Ongoing and future activities. In 1999, four additional wells from Hogan will be redrilled as lateral offsets to the initial horizontal wells. They will target undrained areas identified through the substantiated geological models. The drilling rig will then be moved to Houchin for 10 to 15 redrills and eight workovers. In addition, POOI will start a pilot waterflood on Hogan and Houchin. Later, POOI will drill six to 15 extended-reach wells from Hogan back to the state leases and initiate a full-scale waterflood in the field. Additional recompletions and redrills also will be performed. Lessons learned. For a competitive return on investment in redevelopment projects, lower initial production rates and reserves require low drilling and completion costs. One-trip whipstock systems — as opposed to traditional section milling — were important to minimizing rig time and simplifying operations. Coarse-slotted liners helped control sand production, but some sand-asphaltene plugging still occurred. Since the wells were not gravel packed, they could be perforated to restore the original production rate. The experience from rod guiding in highly deviated wells in the early workovers allowed the wells to be produced with rod-driven PCP systems. The simplified perforated completions using PCP systems to produce moderate amounts of sand greatly reduced completion costs. Acknowledgment U.S. Dept. of Energy’s Office of Fossil Energy. The authorsSteven F. Coombs is senior vice president of Pacific Offshore Operators, Inc. He has 18 years of experience, a large portion of which is in California. He holds a BS in petroleum engineering from the Colorado School of Mines. Edwin Edwards is senior geologist at Pacific Offshore Operators. He has 34 years of experience as a geologist, spending most of his career in California offshore. He holds a BS in geology from the University of California at Los Angeles. William Fleckenstein, senior development engineer at Pacific Offshore Operators, has 13 years drilling and completion experience. He earned a BS and an MS in petroleum engineering from the Colorado School of Mines, where he is currently completing requirements for a PhD. Copyright © 1999 World

Oil |

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)